行星减速器的核心功能

行星减速器是现代齿轮机构中必不可少的部件。他们擅长平稳地移动权力。它们降低了速度,提高了扭矩。这些系统具有太阳齿轮、行星齿轮和环形齿轮的特殊设计。这些部件连接起来均匀地分担负荷。这种设计增加了扭矩输出。它还使业务稳定可靠。紧凑的行星式设计在狭小的空间中也能发挥出色的性能。它非常适合空间有限的应用。

为什么效率在齿轮机构中很重要

效率是任何机械系统的重要组成部分。它影响能源使用、运营成本和环境保护。行星减速机提供高传动效率。他们的多齿轮接触系统减少能源浪费在电力传输。它在重载下保持运行稳定。通过有效利用能源,这些减速器有助于各行各业节约成本,实现绿色运营。

对性能有贡献的关键组件

行星减速机的性能依赖于几个关键部件:

太阳齿轮:它位于中心,驱动附近的行星齿轮。

行星齿轮这些围绕太阳齿轮转动,并与环齿轮连接。

环形齿轮环绕行星齿轮,它提供了一个外部接触点。

这些组件提供均匀的扭矩分配和减少磨损。使用坚固的材料,如淬火钢,提高了耐用性和使用寿命。

行星减速器如何提高扭矩和负载能力?

转矩分配在效率中的作用

行星减速器的一个关键特点是它们能够在多个齿轮上均匀地分配扭矩。这种多点连接减轻了单个部件的压力。增强了系统的可靠性。这种均匀的扭矩共享提高了效率。它还通过切削磨损延长了减速器的寿命。

利用行星系统增强承载能力

行星系统是用来处理大负荷而不损失性能的。他们的小而坚固的设计管理高径向和轴向力。这使它们成为重型工作的理想选择。例子包括建筑机械、起重设备和工业机器人。

平衡紧凑的设计和高性能

即使它们的小尺寸,行星减速机提供顶级性能。他们的智能工程明智地利用空间,同时保持高扭矩输出。这种轻盈的结构和强大的能力使它们至关重要。它们在空间效率和高性能是关键的行业中很重要。

为什么行星减速机在精密应用中是首选?

用行星系统实现高精度

精密任务要求精确性和可靠性。行星减速机在这些领域闪耀。他们的螺旋形齿轮提供平滑的接触和减少的间隙。这支持机器人和航空航天工程等工作的精确控制。

最大限度地减少机械操作中的能量损失

在精密应用中,能源效率是保持高性能的关键。行星减速器以其高效的齿轮设计减少了能源浪费。它们的传输效率达到95%以上。这样可以以最小的损耗提供最大的功率。

行星减速机的耐久性和寿命

耐用性是行星减速机被选为精密任务的首要原因。这些系统由渗碳钢等高质量材料建造,可以承受恶劣的条件。其坚固的设计确保了始终如一的性能。它降低了维护需求和停机时间。

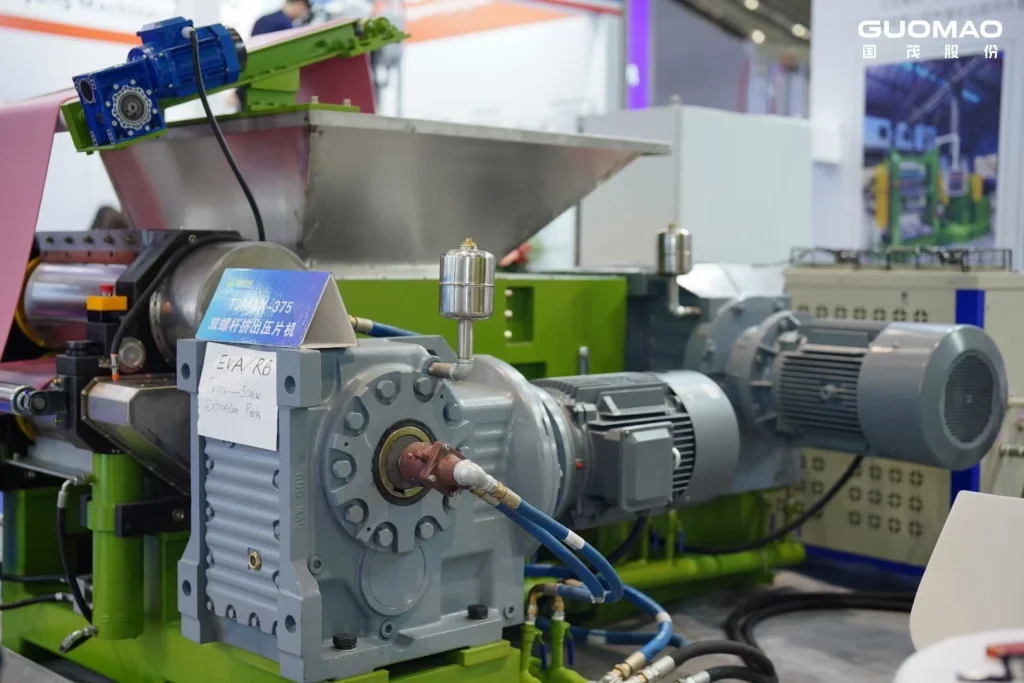

为什么选择国茂提供高质量的行星齿轮箱?

国茂行星减速机背后的先进工程技术

国茂的行星减速机是用当前的工程方法制造的。它们保证了卓越的性能。紧凑的行星设计在小空间内提供强大的性能。它适合空间有限的应用。每个单元都是精确构建的,以实现高扭矩输出和效率。减少了运行过程中的能源浪费。使用先进的技术,如螺旋形齿轮,确保平滑的接触。它减少了反弹,提高了精度。

国贸提高效率的材料和技术

的耐久性和效率 国茂机械行星齿轮箱 来自一流的材料和现代化的技术。所有卫星齿轮和太阳齿轮都是螺旋形的,外壳硬化到58-62 HRC。

我们的 精密行星减速机 导致巨大的传输效果。全补针轴承提高扭转刚度。IP65防护等级屏蔽灰尘和水射流。这些特点提高了减速机的可靠性和使用寿命。

国茂行星减速机的特点

紧凑的设计与优越的扭矩能力

国茂的行星减速器以其小巧的设计和高扭矩的能力而得到认可。我们在多个档位上均匀分配扭矩。这减轻了单个部件的压力。它提高了系统可靠性。这使得它们非常适合在狭小空间中执行需要强大性能的任务。例子包括机器人和航空航天工程。

满足不同工业需求的定制选项

国茂知道各行各业都有不同的需求。我们提供了许多定制选项为我们的 非标准定制减速器我们的选择包括精确的计算、性能设计、高效的解决方案和高适应性。这种灵活性可确保企业获得适合其特定运营需求的解决方案。

跨应用程序的可靠性和一致性能

可靠性是国茂行星减速机的主要特点。由渗碳钢等坚固材料建造,我们可以应对恶劣的条件。我们保持传输效率在95%以上的性能。这确保了以最小的浪费提供最大的电力。其坚实的设计支持在建筑机械和精密工具等应用中保持一致的性能。这种可靠性减少了停机时间和维护成本。

常见问题解答

问:是什么让国茂行星减速机脱颖而出?

答:国茂行星减速器设计小巧,转矩能力高。我们使用当前的工程方法和螺旋形齿轮进行精确接触。我们还具有针对环境因素的IP65保护。

问:国茂的行星减速机适合重型应用吗?

A: 是的。这些系统可以在不损失性能的情况下处理大负载。它们坚固而小巧的设计支持了这一点。

Q: 我可以从国贸定制行星减速器吗?

A: 是的。国贸提供非标准定制选项。这些旨在满足不同行业的不同机械需求。

问:哪些行业从使用Guomao的循环还原器中受益最大?

答:像机器人、航空航天工程和建筑机械这样的行业收益很大。汽车制造和可再生能源领域也受益于这些高性能解决方案。

问:与竞争对手相比,国茂行星减速机的耐用性如何?

A: 我们采用表面硬化钢等优质材料制成,能够承受恶劣的条件。先进技术,如全套滚针轴承,延长了其使用寿命。