Why Coaxial Helical Gearboxes Continue to Matter in Industrial Power Transmission

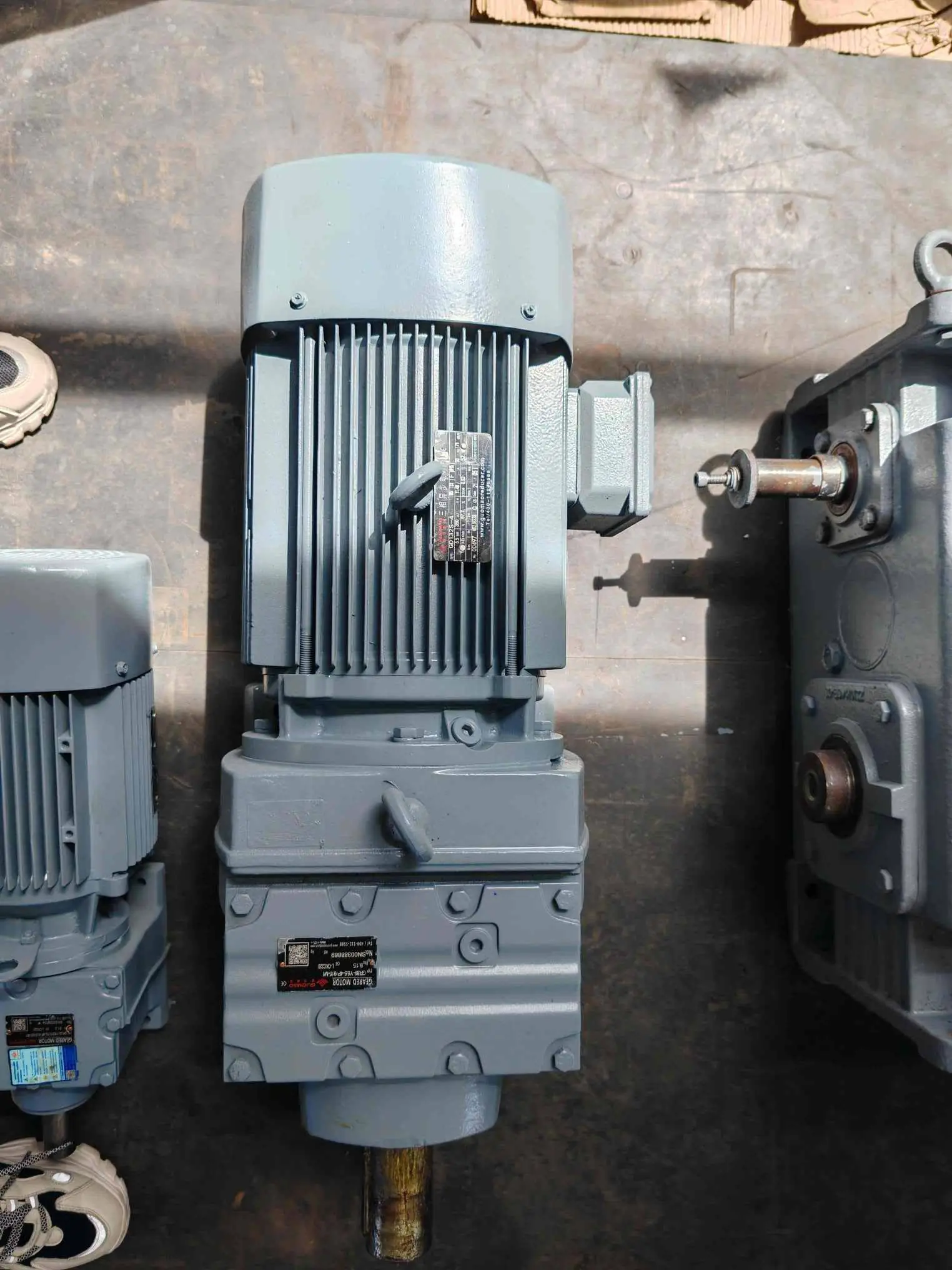

Coaxial helical gearboxes continue to matter in industrial power transmission because their inline structure balances efficiency, mechanical stability, and layout simplicity. As industrial equipment becomes more compact while performance expectations increase, designers increasingly prefer drivetrain solutions that minimize alignment risk and energy loss. A coaxial helical gearbox achieves this by keeping the motor and output shaft on the same axis, creating a direct and efficient torque path.

From a day-to-day view, coaxial helical gearboxes fit ongoing work setups nicely. They send forces smoothly. Their steady action cuts, shakes, sounds, and steady wear. Thus, these designs prove useful in moving goods, handling materials, and auto-making spots. There, any stop in work hurts production right away.

How inline helical gearbox design supports efficiency, compact layouts, and system reliability

An inline helical gearbox build aids energy savings by keeping the drive simple. Power moves along one line. So, it needs fewer parts to fix line-up issues or turns. Helical gears boost this further. They spread the weight slowly over several teeth. This lowers rub spots and focused strain.

Tight setups gain from this method too. You can line up motors, gearboxes, and linked machines in a direct row. This cuts the need for tricky mount setups. In the long run, such plainness boosts overall trust. Fewer pieces face shakes or uneven weights.

Why global buyers are re-evaluating coaxial helical solutions for 2026 projects

Global buyers are re-evaluating coaxial helical solutions for 2026 projects because lifecycle performance has become more important than nominal catalog ratings. Rising energy costs and tighter maintenance resources push procurement teams to focus on efficiency retention, thermal stability, and long-term reliability. Properly selected coaxial helical gearboxes typically generate less heat and experience more uniform wear.

Modular coaxial helical bases aid standard use in various jobs, too. You can adjust ratios, mount types, and motor matches easily. This saves design work. It also makes spare parts fit better across sites.

How a Coaxial Helical Gearbox Works: Design Logic and Performance Fundamentals

A coaxial helical gearbox reduces speed and increases torque through one or more stages of helical gears arranged along a common axis. This configuration enables high torque density without increasing overall footprint and helps engineers evaluate performance beyond headline specifications.

The performance fundamentals of coaxial helical gearboxes depend on gear geometry, material quality, and manufacturing accuracy. When these elements are consistently controlled, the gearbox operates with low noise, high efficiency, and predictable service life under demanding conditions.

The role of helical gear geometry in torque transmission and noise reduction

Helical gear shape aids force transmission through step-by-step tooth contact. Weight shifts bit by bit, not all at once. This cuts shakes and work sounds. So, coaxial helical gearboxes work well where smooth action counts.

Step-by-step contact also helps share weight under changing force. It lowers the strain on single teeth. This backs a longer gearbox run.

What coaxial (inline) shaft alignment means for mechanical stability and motor integration.

Coaxial shaft alignment enhances mechanical stability by minimizing bending moments on shafts and bearings. When the motor shaft aligns directly with the gearbox input, coupling accuracy is easier to maintain, reducing bearing wear during long operating cycles.

A straight-line setup also makes motor fitting easier. Standard IEC motors attach right away with base or edge mounts. They keep the drive layout solid.

Coaxial Helical Gearbox vs Other Gearbox Designs: Key Selection Differences

You must compare gearbox types to avoid wrong fits between job needs and drive setup. Coaxial helical gearboxes do not work for every case. But they shine in straight-line send situations.

Comparing coaxial helical gearboxes with parallel shaft solutions in real installations

Side-line shaft gearboxes get picked for their toughness. But their shifted lines make machine setups harder. Coaxial helical gearboxes keep a direct power route instead. This eases fitting and saves room.

In real use, coaxial types send fewer shocks to nearby parts. This helps auto lines and exact moving systems.

When helical-bevel or worm gearboxes become a better engineering choice

Helical-bevel gearboxes fit 90-degree sends where space rules need direction shifts. Worm gearboxes may work for self-hold or big slowdown needs. They have lower energy savings, though.

Industrial Applications Where Coaxial Helical Gearboxes Deliver the Most Value

Coaxial helical gearboxes add the most value in jobs that need steady runs, even force send, and small system builds.

Typical use cases across conveying, processing, and automation systems

Conveying systems rely on coaxial helical gearboxes to maintain steady speeds under variable loads. Belt conveyors, screw conveyors, and bucket elevators benefit from inline drives that reduce vibration and simplify maintenance.

Processing and automation systems also favor coaxial designs. Mixing equipment, dosing systems, and automated assembly lines require predictable torque and low noise to maintain consistency.

Load profiles, duty cycles, and operating conditions that favor coaxial designs

Coaxial helical gearboxes do best with steady or somewhat changing weights plus long run times. Long work at even speeds lets users tap the full structure energy savings.

Good fitting and care stay vital. Skip direct high-water washes. They harm seals and oil setups.

Coaxial Helical Gearbox Wholesale 2026: A Sourcing Checklist for Industrial Buyers

Coaxial helical gearbox wholesale sourcing in 2026 requires structured evaluation beyond headline specifications. Buyers increasingly assess how technical design, manufacturing quality, and support capability align with real operating conditions.

Core technical parameters to evaluate before shortlisting suppliers

Power range, torque density, and service factor alignment

Power span and force pack must fit true weight spots, not just listed numbers. Pick service factor based on weight changes, start-stop counts, and run length.

Housing strength, sealing design, and thermal performance

Case firmness impacts bearing line-up and lasting steadiness. Seal build and heat work decide if the gearbox runs well in dirt, temp shifts, and steady weights.

Manufacturing and quality indicators that affect long-term reliability

Gear machining accuracy and heat treatment consistency

Steady gear cutting precision and even heat work ensure good contact action and matching wear in batches.

Bearing selection, lubrication systems, and factory testing

Bearing strength, oil build, and plant tests shape run length and work trust directly.

Commercial and supply-chain considerations beyond technical specifications

Production capacity, lead-time stability, and delivery risk

Firm output levels and steady wait times cut job risks. This helps especially in multi-site setups.

Technical documentation, compliance, and after-sales support

Plain papers, a rule help, and quick post-sale aid are key for long runs and upkeep plans.

Common Mistakes in Coaxial Helical Gearbox Selection and Specification

Pick errors happen when gearboxes seem like swap parts, not key system pieces.

Why catalog data alone can lead to undersized or over-engineered gearboxes

List ratings use set conditions that may not match real spots. Heat, weight swings, and mount angles change results a lot.

Overlooking real operating conditions in industrial environments

Skipping outside factors like dirt, air, heat, and upkeep reach can cut gearbox life. It also raises stop times.

How Guomao Supports Accurate Coaxial Helical Gearbox Selection and Deployment

Engineering-driven configuration support for complex applications

在 国茂, we see coaxial helical gearbox picks as a build task based on true run facts. We check weight shapes, run times, and fit limits before suggesting setups.

Manufacturing capabilities that ensure consistency across gearbox series

我们的 GR斜齿轮减速电机 serves as a main coaxial helical choice. It fits straight, sends in moving, blending, and auto gear. Modular helical sets give good energy savings, low sounds, and bendy mounts. They keep steady results.

For jobs needing other ratios or layouts, GF系列平行轴-斜齿轮轮减速电机 options get checked with coaxial ones. This ensures the best drive fit.

Long-term technical support that reduces lifecycle and maintenance risk

After sending, we stress plain papers and job help over the gear’s full life. This cut stops and lengthens runs.

常见问题解答

Q: Which coaxial helical gearbox brand is suitable for industrial applications?

A: Suitable brands typically demonstrate strong manufacturing control, modular product platforms, and proven field performance. Consistency in gear machining, testing standards, and technical support is often more important than brand visibility.

Q: How to choose a coaxial helical gearbox for conveying systems?

A: Selection requires matching torque and service factor to real load conditions, reviewing duty cycle length, and confirming inline installation alignment.

Q: Coaxial helical gearbox vs parallel shaft gearbox, which is better?

A: Coaxial helical gearboxes suit inline layouts and compact systems, while parallel shaft gearboxes may fit certain high-torque or offset configurations depending on space and load requirements.

Q: What matters most in coaxial helical gearbox wholesale sourcing?

A: Key factors include technical suitability, manufacturing quality, delivery reliability, documentation quality, and after-sales technical support.

Q: Are coaxial helical gearboxes suitable for continuous-duty industrial operation?

A: When properly sized and installed, coaxial helical gearboxes are well-suited for continuous-duty operation, offering high efficiency, smooth torque transmission, and stable alignment over long operating cycles.