Industrial Gearbox Selection Checklist: Why Heavy Conveyors Need a Different Approach

The role of industrial gearbox reliability in heavy conveyor uptime

Industrial gearbox reliability plays a key role in heavy conveyor uptime. This is because conveyors in heavy industries work as ongoing load transmission setups, not as backup gear. In mining, ports, cement plants, and bulk material handling sites, conveyors serve as the core of material movement. They connect crushers, stockpiles, and processing units into one smooth chain. If an industrial gearbox breaks down, the downtime often spreads to several processes.

From an engineering perspective, heavy conveyors impose sustained torque, long operating hours, and frequent transient loads on industrial gearboxes. These conditions amplify the impact of selection errors that might be tolerable in light-duty conveyors. As a result, gearbox reliability must be treated as a primary design requirement rather than an afterthought.

Common causes of gearbox failure in heavy-duty conveyor systems

Industrial gearbox breakdowns in heavy-duty conveyor systems usually stem from poor choices at the selection stage. Too-small torque capacity, lacking service factors, and ignored heat limits let gearboxes pass initial tests. Yet they fail too soon in actual use.

Another common issue is not enough focus on bearing and shaft loading. Heavy conveyors create steady side forces from belt pull and material weight. If these forces are not fully included in gearbox choice, bearing wear and gear shift happen slowly. In the end, this leads to major failure.

Industrial Gearbox Operating Conditions That Define Heavy Conveyor Applications

Load characteristics and duty cycles in heavy conveyor systems

Continuous vs intermittent operation and their impact on gearbox sizing

Industrial gearbox sizing for heavy conveyors must begin with a clear understanding of the duty cycle. Continuous-duty conveyors operate near rated torque for extended periods, requiring gearboxes with stable thermal performance and long bearing life. In these applications, thermal capacity and lubrication effectiveness are just as important as mechanical strength.

Intermittent conveyors run fewer hours each day. However, they face greater mechanical pressure from often starting and stopping. Each loaded start brings torque bursts that go beyond normal levels. This adds extra stress to gears, shafts, and bearings.

Shock loads, start-stop frequency, and load fluctuation risks

Shock loads are a defining characteristic of many heavy conveyor systems. Sudden material surges, blocked discharge points, or emergency stops generate transient torque spikes that can exceed nominal values by several multiples. Without adequate service factors, these events cause cumulative fatigue damage even when failures do not occur immediately.

Environmental factors affecting industrial gearbox selection

Dust, moisture, and contamination in mining and bulk handling

Environmental contamination directly affects industrial gearbox durability in heavy conveyor applications. Dust and abrasive particles accelerate seal wear and degrade lubricant cleanliness, while moisture ingress reduces lubrication performance. Gearboxes operating in such environments require robust sealing systems and stable lubrication regimes to maintain reliability.

Ambient temperature extremes and lubrication stability

Surrounding temperature levels affect oil thickness, start torque, and heat release. Hot conditions speed up oil breakdown. Cold ones raise startup resistance. So, heavy conveyor gearboxes should use oil systems that work well over the whole temperature span.

Performance Parameters to Evaluate Before Selection

Torque, power, and speed requirements for heavy conveyors

Calculating required output torque with service factors

Accurate torque calculation is the foundation of industrial gearbox selection for heavy conveyors. Conveyor length, inclination, friction coefficients, and material properties all contribute to real torque demand. Applying realistic service factors ensures the gearbox can absorb transient loads without progressive fatigue damage.

Matching motor power to gearbox thermal capacity

Linking motor power to gearbox heat capacity is often overlooked. Torque might be enough, but running near full power all the time can beat the gearbox’s cooling ability. In heavy conveyors, heat limits often set gearbox life more than just strength does.

Efficiency, heat dissipation, and long-term energy performance

Mechanical efficiency vs real operating efficiency

Listed efficiency figures show best-case setups. These may not match actual heavy conveyor work. Under steady load, even tiny efficiency drops create major heat. This directly hits oil life and bearing work.

When cooling systems become necessary for heavy-duty gearboxes

Cooling steps are needed when basic heat release falls short. Pumped oil or extra cooling keeps temperatures steady in big industrial gearboxes that drive heavy conveyors nonstop.

Industrial Gearbox Design and Configuration Options for Heavy Conveyors

Gearbox types commonly used in heavy conveyor systems

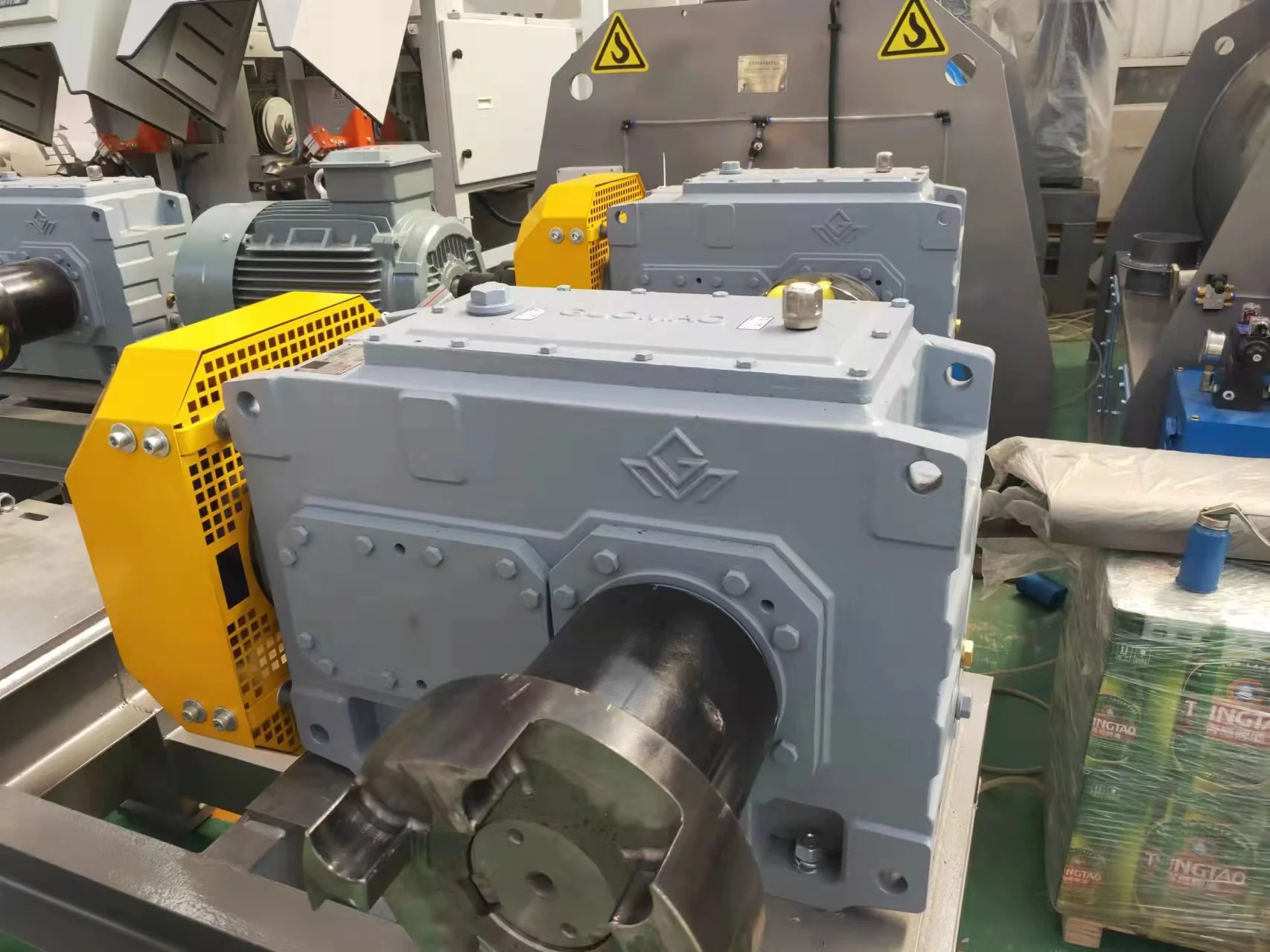

Parallel shaft helical gearboxes for high torque transmission

Parallel shaft helical industrial gearboxes see wide use in heavy conveyor systems. They provide strong torque handling, solid efficiency, and even load spread. Their flexible build allows multi-stage setups. These fit long belt conveyors and bucket elevators under steady load.

In Guomao’s heavy conveyor uses, the H系列摆线平行轴齿轮箱 gets picked when steady torque, good side load resistance, and reliable heat behavior are key. Its tough housing and strong bearing setup keep alignment and dependability under ongoing belt pull.

Bevel-helical and right-angle gearboxes for layout flexibility

Right-angle industrial gearboxes are commonly applied when conveyor layout requires a change in power transmission direction. These configurations are especially useful in vertical conveying or space-constrained installations where alignment flexibility is limited.

In those situations, Guomao uses the B系列垂直轴齿轮箱 to meet mixed torque and side load needs. The upright shaft design allows smooth power flow in small spaces. At the same time, it keeps bearing steadiness under heavy material weight.

Structural and mechanical design considerations

Bearing capacity and shaft load resistance

Bearing choice decides if an industrial gearbox can handle conveyor side and end loads over the years. Heavy conveyors bring steady belt pull that needs to be taken without hurting bearing life or shaft straightness.

Housing strength, rigidity, and vibration control

Housing firmness has a big part in keeping gear lineup. Strong, exact-cut housings cut down shaking. They also hold gearbox shape through long work periods in heavy conveyor runs.

Installation, Maintenance, and Lifecycle Considerations of Industrial Gearboxes

Installation orientation and mounting constraints

Horizontal vs vertical installation impacts

Installation orientation affects lubrication distribution and cooling performance. Industrial gearboxes used in heavy conveyors must be configured according to the actual mounting position to avoid localized overheating or oil starvation.

Shaft alignment and foundation rigidity requirements

Base firmness and shaft lineup directly shape gearbox length of service. Heavy conveyors pass moving forces to the mounting structure. Weak stiffness causes tiny shifts that speed up wear on bearings and seals.

Maintenance accessibility and service life planning

Lubrication methods and inspection intervals

Lubrication strategy strongly affects gearbox service life. Heavy conveyor gearboxes often benefit from forced lubrication systems that maintain oil film integrity under sustained load.

Predicting gearbox lifespan under heavy conveyor duty

Spot-on life forecast relies on true load views. When torque, heat limits, and oil states are set right, industrial gearboxes can run steadily and long even in tough conveyor settings.

How Guomao Industrial Gearboxes Address Heavy Conveyor Selection Challenges

Guomao industrial gearbox portfolio for heavy conveyor applications

在 国茂, industrial gearboxes for heavy conveyors are built around actual work conditions, not just basic specs. Our parallel shaft and vertical industrial gearbox options aim to give reliable torque flow, firm build, and heat stability over long runs.

Engineering support and customization capabilities

We treat industrial gearbox choice as an engineering task. By checking load patterns, work cycles, setup limits, and surroundings together, we make sure each gearbox setup fits real conveyor needs.

常见问题解答

Q: What industrial gearbox type is most suitable for heavy conveyors?

A: Industrial gearbox suitability for heavy conveyors depends on load characteristics, operating speed, and layout. Parallel shaft and right-angle industrial gearboxes are commonly used because they provide high torque capacity and structural stability under continuous-duty conditions.

Q: How to choose an industrial gearbox for a heavy conveyor system?

A: Choosing an industrial gearbox for a heavy conveyor requires accurate torque calculation, appropriate service factors, and verification of thermal capacity. Installation orientation and environmental conditions should also be evaluated early in the selection process.

Q: Are vertical industrial gearboxes suitable for heavy conveyors?

A: Vertical industrial gearboxes are suitable for heavy conveyors when layout constraints require right-angle power transmission. Bearing capacity and lubrication design are critical to ensure long-term reliability in these applications.

Q: Industrial gearbox efficiency vs durability for heavy conveyors, which is more important?

A: Durability is generally more critical than peak efficiency for heavy conveyors, although higher efficiency helps reduce heat generation and supports longer lubricant and bearing life.

Q: Which industrial gearbox brands are commonly used in heavy conveyor projects?

A: Heavy conveyor projects typically select industrial gearbox brands with proven heavy-duty designs, strong engineering support, and the ability to adapt products to real operating conditions rather than relying solely on standard ratings.