Coaxial Helical Gearbox Basics for Industrial Manufacturing Systems

What a Coaxial Helical Gearbox Is and How Inline Power Transmission Works

A coaxial helical gearbox makes inline power transmission possible. It does this by placing the motor and output shafts along the same line. This creates a small and useful drive setup for manufacturing systems. Gears with slanted cuts connect in a smooth way. As a result, they cut down on shaking. They also provide steady output during long production runs. This setup works well for tasks where constant torque and reliable movement matter most.

Structural Design Features of Coaxial Helical Gearboxes: Parallel Shaft Alignment and Helical Gear Engagement

Side-by-side shaft setup and carefully made helical teeth let coaxial helical gearboxes keep good accuracy when carrying loads. The larger area where teeth touch helps share loads better. It also lowers gaps in movement. This leads to smoother turning of the shafts. These features help keep the system steady. They reduce stress on parts in heavy-use setups.

Efficiency, Noise Reduction, and Load Distribution Benefits in Manufacturing Lines

The way helical gears fit together cuts down on sliding rub. This brings good mechanical output and keeps running temperatures lower. Teeth come together step by step. That drops noise and shaking. It makes the work area quieter. Loads are spread out over several tooth areas. This wears down parts less. In turn, it gives a longer working life and fewer care tasks.

Coaxial Helical Gearbox Sizing: Torque, Speed, and Service Factor Essentials

Calculating Required Output Torque for Continuous and Variable Industrial Loads

Correct torque calculation is the foundation of gearbox sizing. Engineers evaluate load inertia, friction, required acceleration, and peak startup torque to avoid overload conditions. Applications such as conveyors or feeders rely on sufficient startup torque to deliver stable performance throughout operation.

Selecting Gear Ratios Based on Input Speed, Output Speed, and Duty Cycle

Picking the gear ratio sets the output speed and torque on hand. Bigger ratios give slower but stronger output. Smaller ratios make for quicker turns. Fitting the ratio to what the process needs is key. For example, slow and strong mixing or even belt moving fits here. This keeps the gearbox working in its best output range.

Understanding Service Factor for Continuous, Shock, and Heavy-Duty Operation

Service factor covers real work conditions that go beyond planned loads. Setups with sudden loads, back-and-forth movement, or many starts need bigger service factors. Steady-run tasks count on well-set service factors. They stop heat overload. They also make sure of lasting reliability.

Thermal Capacity, Lubrication System, and Ambient Condition Considerations

A gearbox’s heat handling decides how well it lets go of heat. Good oiling cuts, rubs, and helps with cooling. Room heat, air flow, and wetness need checking. This stops heat build-up or oil breakdown during long runs.

Verifying Motor Compatibility and Startup Load Requirements

Motor fit makes sure that gearbox weight, torque needed, and start conditions match the motor’s work curve. Right link choices and lining up stop too much load on bearings. They help keep steady mechanical work.

How to Select the Right Coaxial Helical Gearbox for System Integration

Choosing Mounting Orientation, Shaft Design, and Installation Layout

Mounting orientation influences alignment, vibration, and accessibility. Foot-mounted and flange-mounted designs support different machine layouts, while shaft types—solid, hollow, or keyed—must match torque and assembly needs. Proper orientation improves system stability and reduces long-term wear.

Evaluating Gear Materials, Heat Treatment Processes, and Gear Accuracy Levels

A coaxial helical gearbox’s durability depends on material quality and gear manufacturing accuracy. High-strength alloy steel treated through carburizing, quenching, and precision grinding provides strong tooth hardness and long service life. Higher accuracy grades reduce noise and improve motion consistency.

Integrating Gearboxes with Motors, VFDs, and Automated Production Control Systems

Gearbox integration must account for VFD-driven torque variations, acceleration profiles, and load transients. Proper tuning between the motor, gearbox, and drive system maintains smooth operation. Automation systems often rely on gearbox stability to ensure predictable cycle timing.

When to Use Single-Stage Versus Multi-Stage Coaxial Helical Gearbox Designs

Single-stage gearboxes offer high efficiency for moderate reduction. Multi-stage designs provide larger ratios and higher torque, making them suitable for heavy-duty or slow-speed requirements. Engineers consider available space, required output, and system load characteristics when selecting stage configuration.

Environmental Factors: Temperature, Dust, Moisture, and Load Cycles

Heat levels, dirt amounts, and wet air affect seal picks, oil state, and gearbox cooling. Lots of cycling or back-and-forth work calls for stronger load-holding builds. Picking the right case types and oil plans boosts reliability in tough spots.

Comparing Coaxial Helical Gearboxes with Other Industrial Gearbox Types

Coaxial Helical vs Helical-Bevel Gearboxes for High-Torque and Angular Power Transmission

Coaxial helical gearboxes are ideal for inline power transfer, while helical-bevel units serve right-angle arrangements. Although helical-bevel solutions deliver high torque, coaxial helical gearboxes offer higher efficiency and simpler integration where axial alignment is required.

Coaxial Helical vs Planetary Gearboxes for Precision, High-Speed or Compact Designs

Planetary gearboxes excel in precision and torque density, but coaxial helical gearboxes provide easier serviceability and cost-efficiency for large-scale manufacturing. Their simple layout and robust structure support continuous-duty systems better than precision-focused designs.

Coaxial Helical vs Worm Gearboxes for Efficiency and Long-Term Operating Costs

Worm gearboxes achieve large reductions but lose efficiency to sliding friction. Coaxial helical gearboxes maintain higher efficiency and lower energy consumption, making them suitable for facilities focusing on long-term operating cost reductions.

Lifecycle, Maintenance, and Energy Consumption Considerations

Helical gear fits cut rub. This leads to longer oil life, less wear, and fewer care jobs. Savings in energy over long runs help lower total system costs.

Application Suitability Across Heavy, Medium, and Light-Duty Manufacturing

Coaxial helical gearboxes can handle many load types. Hard tasks gain from their torque hold. Medium and easy systems count on their output and steady results.

Coaxial Helical Gearbox Applications Across Modern Manufacturing Industries

Use in Conveyors, Screw Conveyors, Bucket Elevators, and General Material Handling

Coaxial helical gearboxes give steady torque and speed handling for the gear to move stuff. They keep even belt pull and manage changing loads well. That makes them a top choice for belt movers, feeders, and bucket lifters.

Integration in Plastic Extrusion, Rubber Processing, Mixing, and Pulverizing Equipment

Pushing and blending processes need slow, torque-full output. Coaxial helical gearboxes offer solid load spread and heat steadiness. This keeps product quality even in rubber and plastic work.

Increasing Adoption in Chemical, Energy, Paper, Food, and Water Treatment Systems

Pumps, agitators, scrapers, and mixers in these industries rely on predictable torque delivery. The durability of helical gears supports continuous operation in demanding thermal and chemical environments.

Matching Gearbox Duty Ratings to Load Profiles and Production Requirements

Proper duty rating selection ensures effective torque transfer over long operating hours. High-cycling or irregular loads require stronger mechanical margins and robust service factors.

Reducing Downtime and Improving System Stability Across Production Lines

Stable torque and reduced vibration improve line synchronization, reduce component wear, and minimize unexpected downtime.

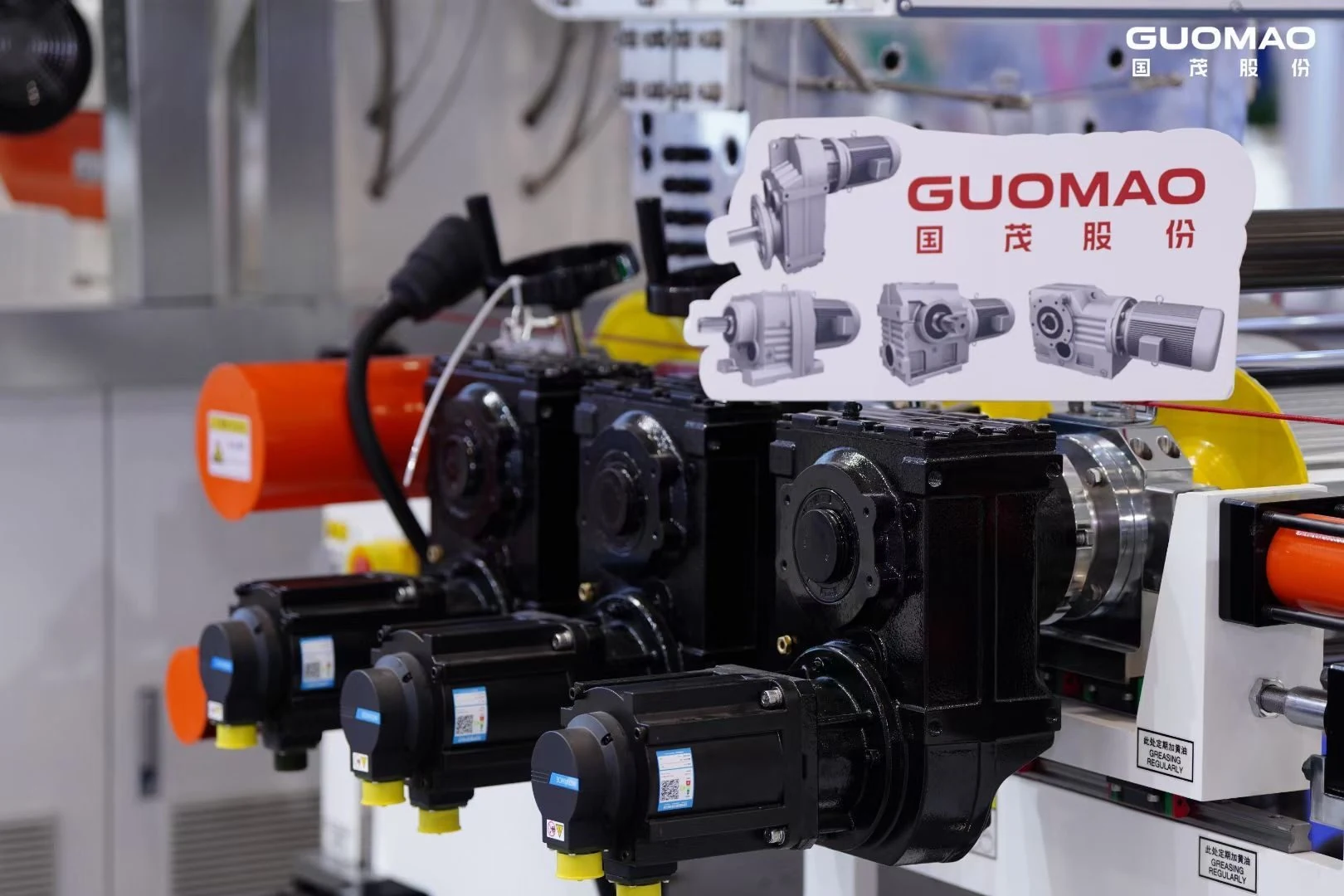

Coaxial Helical Gearbox Solutions from Guomao for Manufacturing Systems

Guomao’s Technical Capabilities in Helical Gear Transmission Systems

在 国茂, we supply helical gear pass systems built for steady industrial work. Our gear know-how, careful machining, and match to world standards make steady, good torque pass possible in manufacturing spots.

Guomao Inline and Parallel-Shaft Helical Gearbox Options for Manufacturing Lines

Guomao brings a few helical gearbox choices:

- GR斜齿轮减速电机 for straight-line or coaxial helical geared motor setups.

- GF Series for side-shaft plans needing a strong torque pack.

- H Series for hard setups with long run times.

These product lines let builders fit a gearbox build to system load and speed needs.

Advantages of Guomao Helical Gearboxes for Throughput, Reliability, and System Efficiency

Guomao gearboxes give strong load holding, block installation, and careful gear finishing. Their low shaking, long working life, and fewer care needs help makers keep an even flow and work output.

Industries and Manufacturing Processes Benefiting from Guomao Coaxial Helical Gearbox Solutions

Our gearboxes are used in areas like stuff moving, chemical work, rubber and plastic making, paperwork, and water care. The trust in our builds helps cut stop times. It also gives sure work results.

常见问题解答

Q: What factors should be evaluated when choosing a coaxial helical gearbox?

A: Required torque, ratio, service factor, thermal capacity, and mounting layout should be assessed. Guomao GR and GF Series models offer multiple configurations for stable operation.

Q: How does a coaxial helical gearbox compare with a planetary gearbox?

A: Planetary gearboxes prioritize precision, while coaxial helical gearboxes deliver easier maintenance, higher efficiency, and better scalability for manufacturing lines. Guomao models are designed for continuous-duty environments.

Q: Which brand is commonly selected for coaxial helical gearbox solutions?

A: Users often prefer gearbox suppliers offering strong load capacity, precision gearing, and modular designs. Guomao provides helical gearboxes suitable for manufacturing applications.

Q: How do engineers determine the correct gear ratio for a coaxial helical gearbox?

A: Engineers evaluate input speed, required output speed, and torque demand. Selecting a ratio within Guomao’s product range ensures efficient system integration.

Q: What industries benefit most from coaxial helical gearboxes?

A: Material handling, chemical processing, rubber and plastics, energy, paper, and water treatment commonly use coaxial helical gearboxes. Guomao solutions support these environments with reliable torque delivery.