Что такое двухэтапная спиральная коробка передач и как она работает для экономии энергии

Двуступенная спиральная коробка передач - это устройство передачи силы, предназначенное для снижения скорости и увеличения крутящего момента. Он снижает входную скорость и увеличивает выходный крутящий момент, используя два последовательных набора спиральных передач. В отличие от одноступенчатых коробок передач, которые делают сокращение в один шаг, двухэтапные разделяют нагрузку на два набора передач. Эта настройка позволяет увеличить коэффициенты сокращения. Это также делает передачу крутящего момента более гладкой и наносит меньшее напряжение на каждый зуб передачи.

Энергия входит через входный вал. Первая пара передач замедляет ее немного. Затем вторая пара передач замедляет ее еще больше, прежде чем она уходит через выходный вал. Этот метод поэтапного снижения позволяет компактные размеры передачи при сохранении высокой эффективности. Результатом является коробка передач, которая потребляет меньше энергии, работает с меньшим уровнем шума и предлагает более длительный срок службы по сравнению со многими альтернативами. Например, в заводских условиях эта конфигурация помогает снизить потребление энергии при сохранении стабильной работы.

Двухступенчатая конструкция распространяет работу. Это снижает износ и тепло. Это делает коробку передач хорошей для долгосрочного использования. Предприятия выбирают его для непрерывной, энергоэффективной работы в требовательных промышленных приложениях.

Преимущества эффективности двухэтапной винтовой коробки передач в промышленных приложениях

Двуступенчатые спиральные коробки передач обеспечивают явное повышение эффективности в жестких промышленных условиях. Их конструкционная конструкция минимизирует потери энергии и повышает общую эксплуатационную эффективность.

Распределение нагрузки и снижение механических потерь для повышения эффективности

Разделяя крутящий момент на два набора передач, каждый зуб несет меньшую нагрузку. Это снижает износ и трение. Это также повышает эффективность, часто выше 95%. Высокая эффективность минимизирует затраты энергии и снижает эксплуатационные затраты на непрерывную работу. Например, на цементном заводе это экономит деньги на счетах за энергию.

Распределение нагрузки помогает передачам длиться дольше. Меньшее трение означает более плавную работу. Компании видят меньшее потребление энергии в ежедневных поездках. Это делает двухступенчатые спиральные коробки передач надежным решением для крупномасштабных промышленных приложений.

Тепловое управление и контроль трения для экономии энергии

Сниженное трение генерирует меньше тепла, что повышает энергоэффективность, продлевает срок службы смазочных материалов и минимизирует потребности в техническом обслуживании. Коробка передач остается в хорошем состоянии для тяжелых работ. В таких областях, как цемент или электростанции, где машины работают весь день, это представляет собой значительное преимущество в непрерывной промышленной деятельности. Например, улучшенное управление теплом позволяет бесперебойно работать на электростанциях.

Эффективное тепловое управление защищает критически важные компоненты и обеспечивает стабильную работу системы. Это означает меньше простоев и большую экономию. Правильное использование масла является ключом к этой выгоде.

Роль материала передачи, профиля зуба и смазки в повышении эффективности

Прочные материалы, такие как затвержденная сплавная сталь, помогают передачам лучше работать. Тщательное формирование зубов и хорошие масляные системы также играют свою роль. Гладкая сетка разрезает крошечные куски трения. Правильная толщина масла поддерживает прочную пленку, увеличивая экономию энергии. Например, точная шлифовка зубов в коробке передач делает ее более плавной и использует меньше энергии.

Материалы и нефть работают вместе. Они предотвращают быстрое изношение передач. Это обеспечивает стабильную эффективность со временем. Компании полагаются на эти функции для долгосрочной прибыли.

Стратегии экономии энергии с использованием двухэтапной винтовой коробки передач

Энергосберегающая мощность двухступенчатых спиральных коробок передач растет с умным дизайном и рабочими привычками.

Соответствующее соотношение коробки передач к спросу на нагрузку, чтобы избежать избыточного размера

Коробки передач слишком большие для работы теряют энергию. Выбор правильного соотношения передач и размера позволяет системе работать в лучшем состоянии. Это позволяет избежать дополнительного использования энергии.

Правильный размер соответствует работе’ с потребностями. Держит энергопотребление низким. Компании экономят, выбирая правильную настройку с самого начала.

Профилактическое обслуживание, надлежащая смазка и уплотнение для минимизации потерь энергии

Регулярные проверки, своевременная замена масла и обслуживание уплотнения поддерживают высокую эффективность. Профилактическая помощь останавливает сбои, которые вызывают пики энергии или простоя. Например, проверка уплотнений на пыльной фабрике обеспечивает хорошую работу передач.

Хорошее обслуживание означает меньшую потерю энергии. Это также снижает расходы на ремонт. Держать масло свежим и плотно уплотнить просто, но это очень экономит.

Использование высокоэффективных конструкций и покрытий для снижения износа и тепла

Теперь производители используют покрытия с низким уровнем трения и лучшие формы зубов. Они сокращают скользящие потери. Они помогают растениям экономить энергию даже в тяжелых условиях. Например, покрытая передача в тяжелой машине работает холоднее и длится дольше.

Эти конструкции уменьшают тепло и износ. Они поддерживают коробку передач эффективной. Это ключ для заводов, которые работают без остановки.

Двухступенчатая винтовая коробка передач против других типов коробок передач: сравнение эффективности и Энергоэкономия

По сравнению с другими типами коробок передач, двухступенчатые спиральные коробки передач предлагают хорошее сочетание эффективности, стоимости и надежности.

| Тип коробки передач | Эффективность | Емкость крутящего момента | Шум и Вибрация | Потенциал энергосбережения |

| Двухступенчатый спиральный | 95%+ | Высокий | Низкий | Отлично |

| Одностепенная спиральная | 96 - 98% | Умеренный | Низкий | Умеренный |

| Червяная коробка передач | 50 - 70% | Низкий до среднего | Высше | Низкий |

| Планетарная коробка передач | 95 - 98% | Очень высокий | Умеренный | Высокий |

| Конечная коробка передач | 93 - 97% | Высокий | Умеренный | Высокий |

Двухступенчатый спиральный vs одноступенчатый спиральный

Одноступенчатые коробки передач хорошо работают при низких коэффициентах. Но они борются с большими сокращениями. Двуступенчатые коробки передач поддерживают высокую эффективность в более широком диапазоне соотношений. Это делает их лучше для работ, требующих высокого крутящего момента при стабильных скоростях. Например, в конвейере двухэтапные передачи лучше справляются с тяжелыми нагрузками.

Одноступенчатые передачи проще. Но двухэтапные передачи более гибкие. Они соответствуют большему количеству задач в отрасли.

Двухступенчатая спиральная коробка передач против червея

Коробки передач червей небольшие и дешевые, но теряют эффективность от скользящего трения. Их эффективность часто снижается до 50-70%. Двуступенчатые спиральные коробки передач остаются выше 95%. Это экономит много энергии, особенно для машин, работающих весь день. Например, червяная коробка передач в конвейере тратит больше энергии, чем спиральная.

Червяные передачи обычно испытывают более быстрый износ, в то время как двухэтапные спиральные передачи обеспечивают более длительный срок службы. Это делает их лучше для крупных рабочих мест.

Двухступенчатая спиральная vs планетарная / скосовая коробка передач

Планетарные и скосные коробки передач эффективны, но дороже и сложнее исправить. Двуступенчатые спиральные коробки передач обеспечивают высокую эффективность и проще обслуживание по более низкой цене. Например, на заводе двухступенчатая спиральная коробка передач дешевле обслуживать, чем планетарная.

Планетарные системы передач предназначены для очень высоких нагрузок, в то время как двухэтапные спиральные коробки передач проще установлять и обслуживать. Они хорошо балансируют стоимость и производительность.

Конструкционные соображения для оптимального выбора двухэтапной винтовой коробки передач

Выбор правильной коробки передач обеспечивает эффективность и долгосрочную надежность.

Вход & Выходная скорость, требования к крутящему моменту, рабочий цикл

Вам нужно знать двигатель’ s входная скорость, выходный крутящий момент и рабочий цикл. Неправильное догадание может снизить эффективность или сократить срок службы передачи. Например, коробка передач для тяжелого конвейера должна соответствовать двигателю’ скорость точно.

Правильный размер поддерживает эффективность системы. Это также предотвращает сбои. Это ключ к непрерывным задачам.

Условия окружающей среды: температура, пыль, ударные нагрузки

Установка работы очень важна. Горячие, пыльные или ударные места требуют дополнительных уплотнений, специального масла и прочных корпусов для поддержания эффективности. Например, в пыльной шахте хорошие уплотнения держат передачи чистыми и эффективными.

Тестовые коробки передач в тяжелых условиях. Правильная конструкция справляется с теплом и грязью. Это держит энергопотребление низким.

Монтаж, ограничения размеров, вес и эффективность пространства

Заводы часто имеют тесные пространства. Двуступенчатые спиральные коробки передач с модульными креплениями, такими как крепление на ногу, крепление на фланце или крепление на вал, хорошо подходят без потери производительности. Например, установленная на фланце коробка передач экономит место на небольшой фабрике.

Модульные конструкции гибкие. Они подходят в тесные места. Это делает систему эффективной и простой в установке.

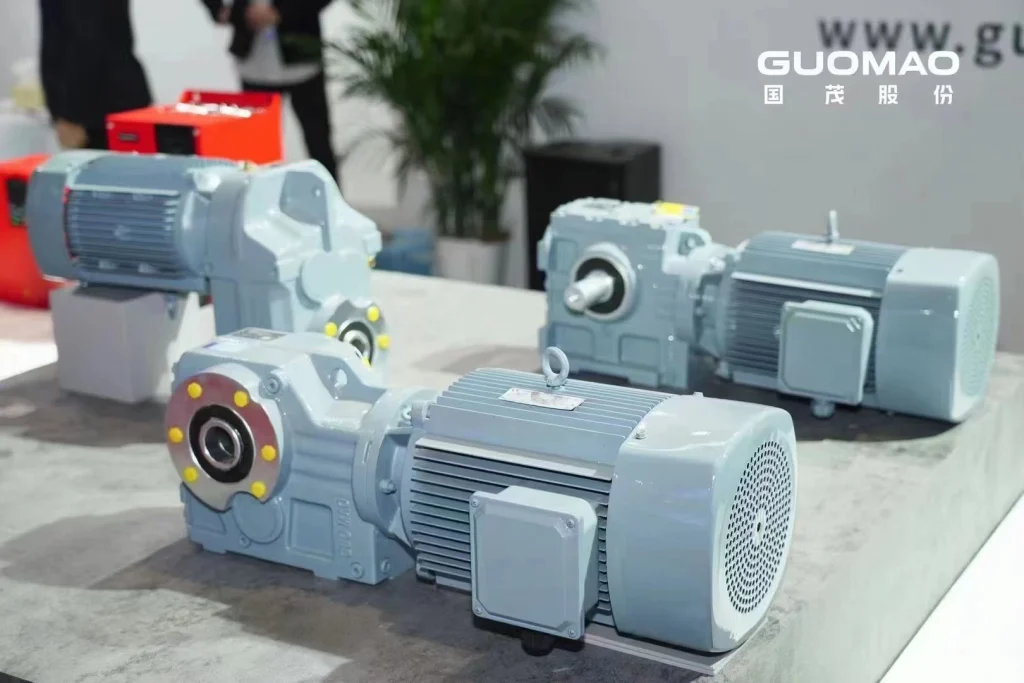

Guomao двухэтапные винтовые коробки передач решения

Обзор компании и технический опыт в области передач передач

В Гумао, мы имеем более 30 лет опыта в проектировании и производстве коробки передач. Наша производственная база охватывает более 530 000 квадратных метров. У нас есть высочайшие испытательные объекты. Мы обслуживаем клиентов по всему миру с точными коробками передач. Guomao стремится поставлять всемирно признанные решения передачи, соответствующие международным стандартам качества. Мы создаем решения, которые экономят энергию и повышают эффективность в таких отраслях, как горнодобывающая промышленность, энергетика и химическая работа.

Guomao соответствует стандартам ISO и DIN. Это обеспечивает качество и доверие. Наши коробки передач хорошо работают в сложных условиях. Клиенты полагаются на нас для стабильной работы.

Ключевые особенности двухэтапной винтовой коробки передач Guomao для эффективности и энергосбережения

Наши двухэтапные спиральные коробки передач построены для:

- Высокая эффективность выше 95%.

- Широкие опции соотношения до 33 000, подходящие для многих рабочих мест.

- Компактная модульная конструкция, доступна в форматах, установленных на ногу, фланц и вал.

- Сильная конструкция, с точностью передачи, соответствующей ISO 6336, и твердостью зубов до HRC 62.

- Низкий уровень шума и тепла, обеспечивая стабильную работу со временем.

Эти функции позиционируют наши коробки передач в качестве предпочтительного решения, обеспечивая значительную экономию энергии и продленную долговечность. Например, в горнодобывающем конвейере они сокращают затраты на электроэнергию.

Применения и отрасли промышленности, поддерживаемые Guomao

Наши двухэтапные коробки передач используются в горнодобывающей, энергетической и химической отраслях. Они экономят энергию и сокращают затраты. Например:

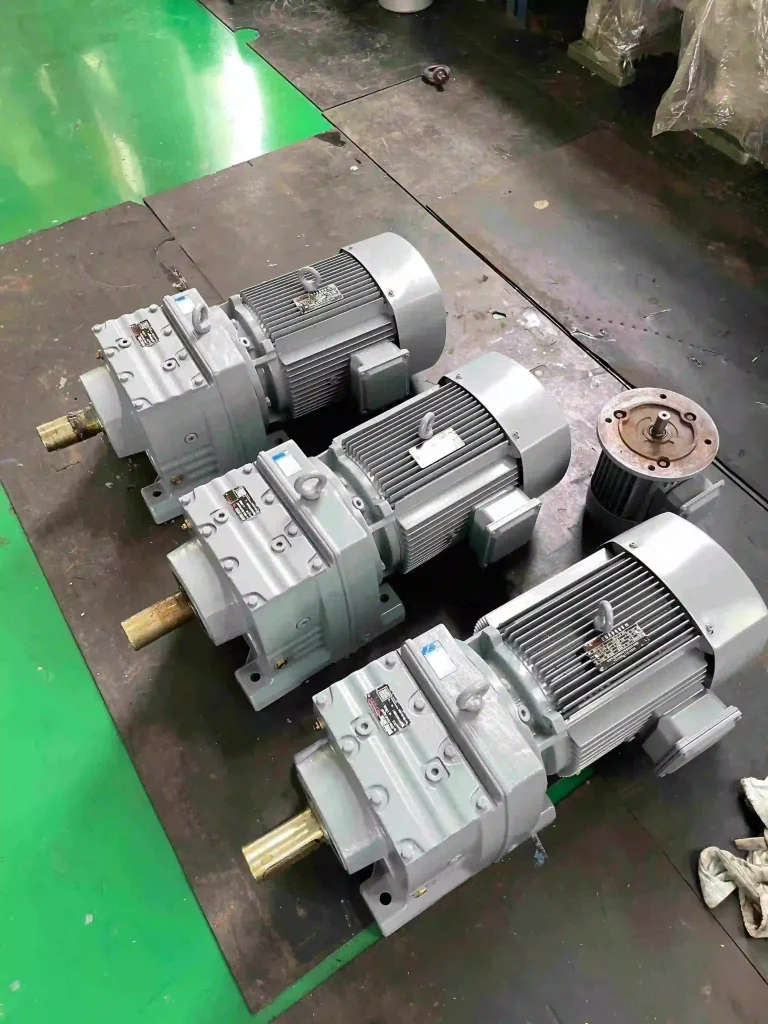

Наши Серия GF спиральный шарнир-мотор с параллельным валом Это ключевой продукт. Он использует две или три ступени спиральных передач. Достигает эффективности выше 95%. Емкость крутящего момента достигает до 50 кН · м. Модульные крепления, такие как нога, фланца и вал, делают его подходящим для конвейеров, подъемных устройств и тяжелых линий обработки. Например, на цементном заводе спиральный редукторный двигатель серии GF с параллельным валом поддерживает плавную работу конвейеров.

Редуктор спиральной передачи серии GR также гибкий. Он предлагает одноступенчатые, двухступенчатые или трехступенчатые установки передач. С коэффициентами до 33 000, он поддерживает системы, такие как гомогенизация передач, транспортировка шламы и ведро конвейеров. Точная обработка сохраняет низкий уровень шума. Сильное жилье обеспечивает долгую жизнь. Серии GF и GR соответствуют стандартам ISO 6336 и DIN 3990. Они соответствуют глобальным эталонам.

События, такие как Производственный мир 2025 Осака показать ценность передовых технологий передач. Guomao’ продукты выделяются инновациями, надежностью и энергосбережением. Наши коробки передач помогают заводам по всему миру работать лучше и экономить энергию.

Часто задаваемые вопросы

В: Что такое двухступенчатая спиральная коробка передач и как она повышает эффективность?

A: Двуступенная спиральная коробка передач сокращает скорость через два набора передач. Он распространяет крутящий момент нагрузки и сокращает потери энергии. Эта конструкция достигает эффективности выше 95%, обеспечивая при этом стабильный крутящий момент.

В: Какие отрасли больше всего получают выгоду от использования двухэтапных спиральных коробок передач?

Ответ: Горнодобывающие, цементные, логистические и энергетические поля получают много. Они нуждаются в непрерывной работе, высоком крутящем моменте и эффективности для снижения затрат.

В: Как двухступенчатая спиральная коробка передач сравнивается с червяной коробкой передач в энергосбережении?

Ответ: Червяные коробки передач работают с эффективностью 50-70% из-за скользящего трения. Двуступенчатые спиральные коробки передач достигают более 95%. Они гораздо более энергоэффективны для тяжелых задач.

В: Какой бренд обеспечивает надежные двухэтапные спиральные коробки передач?

A: Guomao предлагает проверенные двухступенчатые спиральные редукторы передач, такие как серии GF и GR. Они построены для высокой эффективности, гибкости и длительного срока службы.

В: Как выбрать правильную двухэтапную спиральную коробку передач для конкретных приложений?

A: Выбор зависит от крутящего момента, соотношения скорости, рабочего цикла и окружающей среды. Консалтинг с Guomao гарантирует, что коробка передач соответствует потребностям работы, сохраняя при этом энергию.