Введение в модульные системы привода передач

Что такое модульные приводы?

Модульные системы привода передач являются инновационными инструментами передачи передач, построенными с универсальной, стандартизированной структурой. Они полагаются на заменные части, такие как передачи, корпусы, валы и монтажные интерфейсы. Эти детали могут быть расположены различными способами. В отличие от заказных коробок передач, модульные приводы позволяют быструю сборку, более короткие сроки доставки и легкую адаптацию к различным промышленным задачам. Это устраняет необходимость начинать с нуля для каждого проекта.

Почему промышленность переходит на модульные решения

Компании переходят на модульные приводы передач для повышения эффективности, сокращения расходов и сохранения гибкости. Международная федерация робототехники прогнозирует стабильный рост расходов на автоматизацию до 2026 года. Эффективность оборудования является главным приоритетом. Модульные приводы передач удовлетворяют этой потребности. Они обеспечивают адаптируемые решения, снижают затраты на обслуживание и упрощают управление оборудованием. Торговые выставки, такие как Производственный мир Осака 2025 подчеркнуть эту тенденцию. Модульные системы представлены в качестве ключевой особенности будущей промышленной техники.

Преимущества модульных приводных систем передач в промышленных приложениях

Снижение первоначальных инвестиций за счет стандартизированных компонентов

Модульный подход снижает потребность в заказовом производстве. Вместо того, чтобы создавать уникальные коробки передач для каждой работы, стандартизированные детали работают в различных отраслях промышленности. Это снижает первоначальные затраты на проектирование и производство. Это также обеспечивает стабильное качество. Компании экономят деньги при сохранении надежной производительности.

Более низкие затраты на установку и ввод в эксплуатацию

Модульные приводы передач сделаны для простой совместимости. Им нужно меньше настроек во время настройки. Стандартные интерфейсы монтажа и адаптируемые варианты вала ускоряют процесс. Это сокращает время простоя. Для заводов быстрая установка снижает расходы на ввод в эксплуатацию и позволяет быстрее запустить производство.

Долгосрочное обслуживание и экономия запасных частей

Техническое обслуживание и запасные части могут быть дорогими в промышленных операциях. Модульные приводы передач облегчают обслуживание. Их части взаимозаменяемы и легко найти. Замена компонентов быстра и проста. Это сокращает время простоя и уменьшает потребность в больших запасах запасных частей. Операции остаются плавными и экономичными.

Увеличение эффективности и производительности с помощью модульных приводов передач

Высокая эффективность передачи и энергосбережение

Модульные системы привода передач обеспечивают высокую эффективность, часто превышающую 95% в конструкциях спиральных передач. Традиционные червяные передачи менее эффективны. В текущих операциях, таких как конвейеры или экструзионные линии, даже небольшое повышение эффективности экономит значительные затраты на энергию каждый год. Это делает модульные приводы мудрым выбором для компаний, осознающих затраты.

Продолженный срок службы и надежность в суровых условиях

Модульная конструкция позволяет Guomao использовать углеродированные, точно заземленные передачи с высокой прочностью (HRC58-62). Они обеспечивают долговременную производительность. Сбалансированное распределение нагрузки и несколько точек контакта передач повышают долговечность. Это жизненно важно в сложных отраслях, таких как горнодобывающая промышленность и производство стали. Приводы справляются с тяжелыми условиями без частых сбоев.

Гибкость масштабирования и адаптации к различным нагрузкам

Модульные системы сочетают в себе различные ступени передачи и соотношения. Они управляют потребностями в крутящем моменте для небольших упаковочных машин или большого подъемного оборудования. Эта универсальность позволяет компаниям адаптироваться к меняющимся производственным потребностям. Там’ Нет необходимости заменять всю систему. Компании могут легко масштабировать свои операции.

Специфические отраслевые приложения модульных приводных систем передач

Применения в энергетической и горнодобывающей промышленности

В горнодобывающих и энергетических областях модульные приводы передач управляют лентовыми конвейерами, дробителями и подъемными машинами. Их прочная конструкция справляется с тяжелыми ударными нагрузками и разными скоростями. Эти условия распространены в сложных условиях. Приводы обеспечивают стабильную производительность, уменьшая дорогостоящие задержки.

Пластиковые, резиновые и экструзионные машины

Экструзионные машины нуждаются в точном регулировании крутящего момента и тяги. Гуомао’ Модульные решения, такие как серия G и планетарные редукторы, используются в пластиковых и резиновых экструдерах, смешивачах и календарах. Регулируемые соотношения передач обеспечивают последовательную производительность и надежное качество продукции. Такая точность имеет решающее значение для производства.

Приложения для транспорта, порта и обращения с материалами

Порты и логистические центры используют приводы передач для кранов, контейнерных погрузчиков и автоматизированных конвейеров. Модульные приводы передач поддерживают различные установки монтажа. Они хорошо работают в узких или модернизированных пространствах. Их высокая мощность крутящего момента и надежность минимизируют время простоя в бесперебойных операциях.

Модульные приводные системы по сравнению с традиционными приводами передач

Анализ затрат на весь жизненный цикл: CapEx vs OpEx

Традиционные приводы передач могут иметь более низкие первоначальные затраты. Однако модульные системы экономят больше в долгосрочной перспективе. Они сокращают время простоя, упрощают обслуживание и снижают расходы на запасные части. Это приводит к лучшей общей стоимости владения над оборудованием’ с жизнью. Компании получают долгосрочную экономию.

Эффективность, надежность и энергоэффективность

Традиционные коробки передач теряют эффективность, когда они носятся. Их фиксированные конструкции ограничивают гибкость. Модульные приводы передач поддерживают высокую эффективность с помощью точных заземливаемых передач и улучшенных систем смазки. Они работают надежно в суровых условиях. Это делает их идеальными для отраслей, требующих последовательного времени работы.

Гибкость и настройка для потребностей современной промышленности

Традиционные приводы созданы для конкретных задач, что ограничивает их использование. Модульные приводы передач предлагают несколько настроек из одной системы. Это снижает потребность в уникальных конструкциях. Компании могут легко расширять или корректировать производственные линии, сэкономив время и деньги.

Проблемы в переключении и то, как Guomao предоставляет решения

Переход на модульные системы может вызвать беспокойство по поводу установки с существующим оборудованием. Guomao решает это с помощью стандартизированных интерфейсов. Наши модульные коробки передач плавно интегрируются в большинство систем. Это снижает время простоя во время переключения. Наши решения делают переход на модульную технологию беспрепятственным.

Гуомао’ Модульные решения привода передач и конкурентные преимущества

Портфель продуктов: серия G, серия HB, планетарные и точные редукторы

В Гумаомы предлагаем широкий спектр модульных систем привода передач:

- Редукторы передач серии G (GR, GK, GS, GF)Стандартизированные конструкции, которые работают с различными типами двигателей, входными мощностями и формами установки.

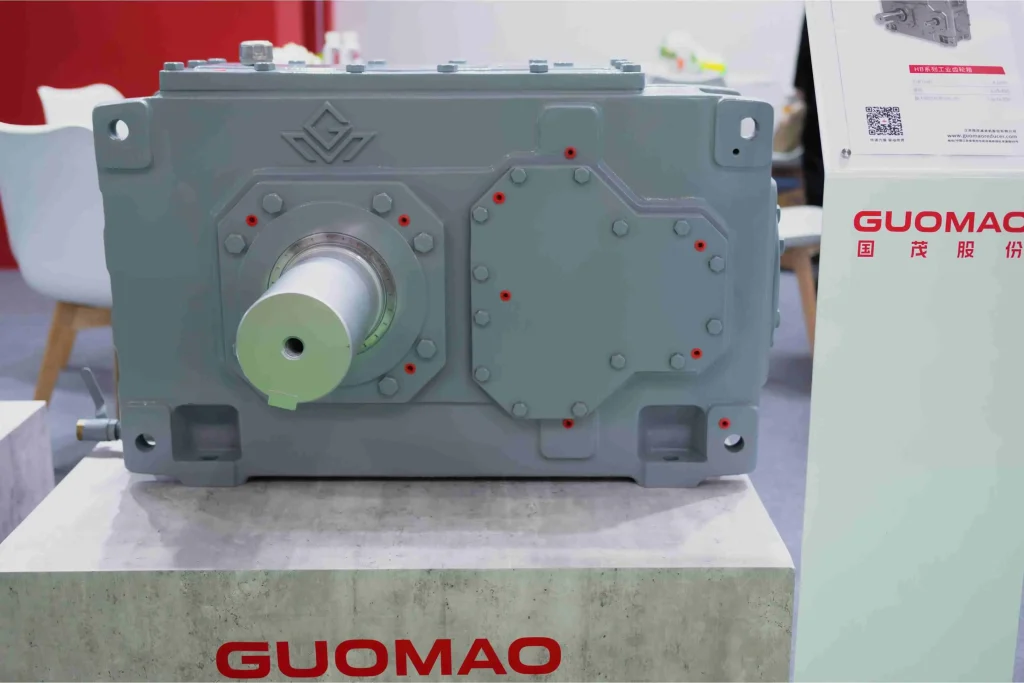

- Промышленные коробки передач серии HBСовременные модульные коробки передач, которые соответствуют глобальным брендам. Они предлагают гибкие варианты смазки и охлаждения.

- Точные планетарные редукторыКомпактные приводы для робототехники, станков и аэрокосмической промышленности с высокой точностью и защитой IP65.

- Инженерные планетарные редукторыПостроен для потребностей в высоком крутящем моменте в строительстве и морской инженерии.

Доказанная надежность во всех мировых отраслях

Наши приводы передач пользуются доверием в горнодобывающей промышленности, пластмассах, логистике и возобновляемых источниках энергии. Модульная конструкция обеспечивает универсальность во всех секторах. Клиенты пользуются последовательным качеством и надежной производительностью.

R& D Прочность и модульные возможности настройки

Guomao имеет более 30 лет R & amp; D Опыт. Мы используем передовые тесты для улучшения модульных платформ. Наши индивидуальные настройки сохраняют преимущества стандартизации. Это дает клиентам гибкость и экономию затрат.

Ориентированное на клиента обслуживание и долгосрочное партнерство

В Guomao мы сосредоточены на чем-то большем, чем просто продукты. Мы создаем сильные партнерские отношения. Наш ориентированный на клиента подход включает техническую поддержку, планы технического обслуживания и глобальную цепочку поставок запасных частей. Это обеспечивает надежную работу во всем мире.

Часто задаваемые вопросы

В: Какая марка модульных систем привода передач надежна для промышленного использования?

О: Гуомао известен своим широким портфелем модульных приводов передач. Он сочетает в себе стандартизированный дизайн с доказанной производительностью во многих отраслях.

В: Как выбрать модульные продукты привода передач для тяжелых приложений?

A: Посмотрите на крутящий момент, номинальную мощность и условия установки. Гуомао’ Серии G и HB являются масштабируемыми, охватывающими легкие машины и системы с высоким крутящим моментом.

В: Каковы преимущества модульных систем привода передач по сравнению с традиционными приводами передач?

Ответ: Модульные системы сокращают затраты на жизненный цикл, повышают энергоэффективность и предоставляют больше вариантов настройки, чем фиксированные традиционные конструкции.

Q: Что делает Guomao’ с модульные системы привода передач экономически эффективны?

A: Стандартизированные детали, быстрая установка и легкое обслуживание уменьшают как первоначальные, так и текущие затраты, делая Guomao’ Системы с высокой эффективностью.

В: Кто ведущие компании, предоставляющие модульные системы привода передач?

A: Guomao выделяется десятилетиями опыта, передовых R & amp; D, и глобальная клиентская база в горнодобывающих, пластмассовых, энергетических и логистических секторах.