Различные отрасли промышленности требуют надежного оборудования, способного выполнять сложные задачи. Эти приложения охватывают такие отрасли, как производство, возобновляемая энергия, робототехника и автомобильная промышленность. Подшипники планетарных передач являются важными компонентами, обеспечивающими эффективную работу машины при сохранении конструктивной целостности. Для таких компаний, как Guomao, известных отличными системами передач, эти подшипники играют решающую роль в обеспечении надежной передачи энергии. Сегодня’ В промышленном ландшафте, где машины требуются для обработки значительных нагрузок, роль этих подшипников имеет решающее значение. Они поддерживают отрасли, которые нуждаются в сильном, стабильном оборудовании для удовлетворения растущего спроса.

Что такое подшипники планетарных передач?

Планетарные подшипники передач являются ключевыми компонентами систем передачи энергии. Они эффективно обрабатывают высокие нагрузки. В отличие от обычных подшипников, они разделяют нагрузку на несколько передач. К ним относятся солнечная передача, планетарная передача и внешняя кольцевая передача. Ни одна передача не берет все давление. Эта конфигурация эффективно обеспечивает высокую силу при сохранении компактной конструкции.

Гумао интегрирует эти подшипники в свои редукторы передач, повышая производительность машины в жестких условиях. Конструкция помогает машинам справляться с тяжелой работой без слома.

Ключевые преимущества подшипников планетарных передач в высоконагрузочных приложениях

Улучшенное распределение нагрузки

Планетарные подшипники равномерно распределяют нагрузку между несколькими передачами. В сложных задачах машины сталкиваются с большим напряжением. Такое совместное использование снижает вероятность слома. Каждая передача несет только небольшую часть нагрузки. Это способствует длительной долговечности системы. Это также обеспечивает последовательную производительность. Это’ идеально подходит для применения в горнодобывающей, строительной и промышленной среде. Гуомао’ редукторы передач предназначены для выдержания значительных нагрузок. Они поддерживают надежную работу в течение длительного периода времени. Это важно для машин, которые работают весь день под сильным давлением. Подшипники гарантируют, что система остается прочной и надежной.

Компактная конструкция с высокой плотностью крутящего момента

Эти подшипники компактны, но очень эффективны, способны доставлять значительную силу в узких пространствах. Это идеально подходит для применения в робототехнике и автомобильной промышленности, где пространство ограничено. Они обеспечивают более высокий крутящий момент по сравнению со стандартными передачами. Гуомао’ редукторы передач s Они компактны, но мощны, что позволяет эффективно работать в ограниченных пространствах. Это’ идеально подходит для мест, где пространство имеет значение, но требуется сила. Например, в робототехнике небольшим системам необходимы сильные подшипники для перемещения тяжелых деталей. Гуомао’ Дизайн идеально отвечает этим потребностям.

Улучшение эффективности и долговечности

Тяжелые работы генерируют трение, что приводит к накоплению тепла и износу материала. Подшипники планетарных передач сокращают трение. Снижая внутреннее трение, эти подшипники минимизируют потери энергии и продлевают срок службы системы. Гуомао использует изысканные материалы. Они строят редукторы передач тщательно. Они длились долго, даже в тяжелых местах. Меньшее трение означает, что машины работают лучше. Необходимо меньше ремонта. Это ключ для отраслей, которые могут’ t позволить себе простой. Подшипники поддерживают хорошую работу машин в течение длительного времени.

Общие применения подшипников планетарных передач в условиях высокой нагрузки

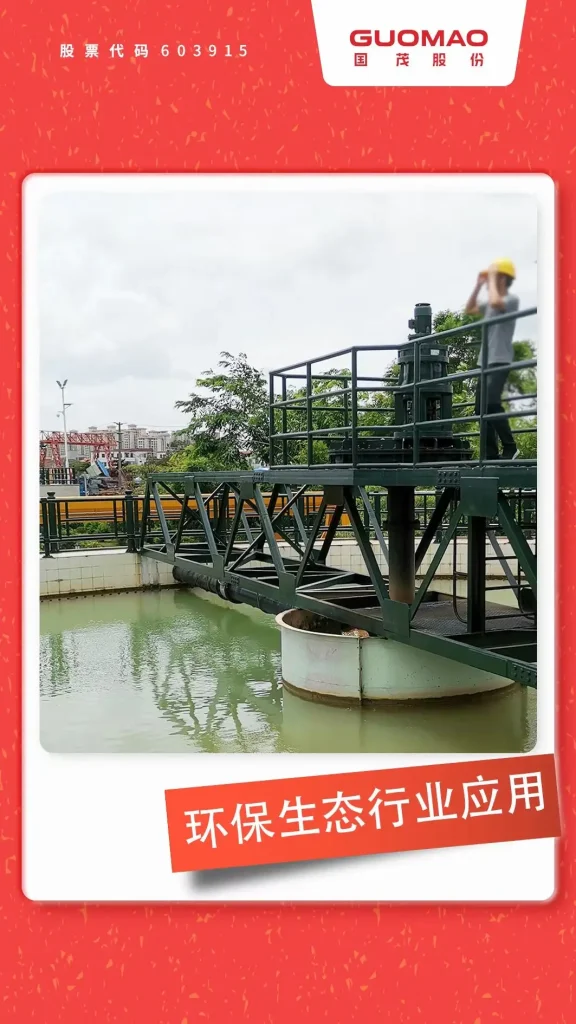

Промышленное оборудование

Большие машины несут тяжелые нагрузки. К ним относятся конвейеры, смешители и дробители. Планетарные подшипники передач обеспечивают плавную и надежную работу. Они распределяют нагрузку равномерно между несколькими передачами. Это останавливает разрывы. Гуомао’ редукторы передач созданы для сложных задач. Они продолжают работать в тяжелых условиях. Это очень важно для заводов, которые работают весь день. Подшипники обеспечивают, чтобы машины оставались прочными и надежными. В горнодобывающей промышленности машины поднимают тяжелые породы, с подшипниками планетарных передач, обеспечивающими плавную работу.

Системы возобновляемых источников энергии

Ветровым турбинам нужны надежные системы передач. Планетарные подшипники передач превращают движение лезвия в энергию. Они предназначены для надежной работы в суровых условиях окружающей среды. Они длились долго. Гуомао’ Решения для ветровой энергии используют эти подшипники. Они поддерживают хорошую работу турбин. Это означает меньше фиксации. Это способствует увеличению производства энергии. Другие системы зеленой энергии также используют эти подшипники для стабильной работы. Например, солнечным трекерам нужны сильные передачи для перемещения панелей. Планетарные подшипники передач помогают им оставаться точными и прочными.

Автомобиль и робототехника

Автомобили и роботы нуждаются в точном оборудовании для тяжелых задач. Планетарные подшипники передач дают силу и точность. Они’ Используется в электромобилях и роботах. Гуомао’ редукторы передач помогают этим областям. Они надежны и точно спроектированы. Это важно для машин, которые должны двигаться быстро и нести большие нагрузки. Подшипники поддерживают хорошую работу систем под напряжением. В электромобилях они помогают двигателям работать плавно. В роботах они обеспечивают точные движения для тяжелой работы.

Выбор правильных подшипников для вашего приложения

Выбор лучших подшипников означает проверку нескольких вещей. К ним относятся потребности в нагрузке, условия работы и помещение. Правильный выбор позволяет машинам работать лучше. Это улучшает систему’ с долговечностью.

Типы и размеры нагрузки

Разные задачи требуют разных сильных сторон. Некоторым нужны радиальные нагрузки. Другие нуждаются в аксиальных нагрузках. Некоторым нужны оба. Выберите подшипник, который соответствует задаче. Guomao предлагает редукторы передач для всех видов нагрузок. Это помогает соответствовать вашим потребностям. Подшипники справляются с большими силами без слома. Это ключ к тяжелым задачам на фабриках или шахтах. Например, в строительстве машины поднимают тяжелые материалы. Подшипники держат их прочными и стабильными.

Экологические условия

Тяжелые задачи часто происходят в тяжелых местах. Тепло, влажный воздух или пыль могут повредить передачам. Выберите подшипники, которые стоят на них. Гуомао’ с Точные планетарные редукторы Высокая защита (IP65). Они разработаны для надежной работы в требовательных условиях, включая шахты и строительные площадки. Это позволяет машинам работать в тяжелой погоде или грязных районах. Например, в пыльных шахтах подшипники должны оставаться прочными. Гуомао’ Дизайн гарантирует, что они это делают.

Требования к пространству и установке

У некоторых задач мало места. Эти подшипники компактны, но очень эффективны, способны обрабатывать значительные нагрузки. Их компактная конструкция позволяет обеспечить высокий крутящий момент в условиях ограниченного пространства. Редукторы передач Guomao разработаны с учетом оптимизации пространства, обеспечивая высокий крутящий момент даже в условиях ограниченного пространства. Это отлично подходит для роботов или автомобилей, где пространство ограничено, но требуется сила. Например, в производстве автомобилей небольшие системы передач должны обрабатывать большие нагрузки. Гуомао’ редукторы идеально подходят.

Часто задаваемые вопросы

В: Какой срок службы подшипников планетарных передач при тяжелых нагрузках?

А: Это зависит от нагрузки, тепла, смазки и ухода. При хорошем обслуживании они могут длиться 50 000 часов и более.

В: Как подшипники планетарных передач сравниваются с другими типами подшипников в приложениях с высокой нагрузкой?

А: Они’ Лучше для тяжелых задач. Они разделяют нагрузки между передачами. Это снижает риски слома. Это делает задачи более плавными.

В: Могут ли подшипники планетарных передач использоваться в экстремальных температурах?

А: Да, с правильными материалами. Гуомао’ редукторы передач работают от -40°C до 50°C.

В: Какие методы обслуживания требуются для подшипников планетарных передач?

А: Проверьте масляние. Ищите одежду. Держите передачи в ряду. Гуомао’ Редукторы требуют малого ухода. Но проверки помогают им прожить.

В: Эффективны ли подшипники планетарных передач для крупномасштабного промышленного использования?

О: Да. Сначала они стоили больше. Но их прочность и низкое обслуживание делают их дешевле со временем. Гуомао’ продукция предлагает исключительную ценность, повышая производительность и долговечность тяжелых машин.