Какие факторы следует учитывать при выборе одного редукционного спирального коробка передач?

Ключевые спецификации для проверки высочайшей производительности

Выбор одной редукционной спиральной коробки передач требует тщательной оценки ее характеристик для обеспечения максимальной производительности. Ключевые факторы, такие как выходная мощность, отношение передач и прочность крутящего момента, имеют жизненно важное значение для выбора. Единоредуктивные спиральные коробки передач могут достичь эффективности до 98% в оптимизированных конфигурациях. Их гибкая конструкция подходит для многих промышленных задач и доступна как в конфигурациях, установленных на ногу, так и на фланце для гибкой установки. Кроме того, убедитесь, что скорость входа соответствует вашему двигателю.

Почему материалы для передач - это большая сделка

Материальный состав передач напрямую влияет на их прочность и долговечность. Виральные передачи, изготовленные из высокопрочная низкоуглеродная сплавная сталь подвергаются карбуризации и гашению. Этот метод значительно повышает передачу’ с прочность и способность нести груз. Они могут выдерживать постоянные тяжелые нагрузки в течение длительного времени работы. Поверхность зуба достигает твердости HRC58-62. Эта долговечность позволяет передачам эффективно выдерживать износ во время постоянного использования. Передовые методы обработки поверхности твердых зубов улучшают точность передачи и снижают шум хода, что приводит к более стабильной работе. Вместе это гарантирует, что ваша коробка передач остается стабильной и надежной, независимо от задачи.

Как нагрузка и скорость влияют на ваш коробка передач Выбор?

Соответствующее коробка передач Сила для ваших потребностей

Важно знать свои потребности в нагрузке при выборе правильной винтовой коробки передач с одной редукцией. Перегрузка может привести к быстрому износу или серьезным повреждениям. Тяжелые приложения требуют коробок передач с тяжелые подшипники и жесткие конструкцииТяжелые спиральные коробки передач обеспечивают крутящий момент до 950 кНм. Они подходят для сложных задач, таких как подъемные машины, двигатели материалов или конвейерные системы. Номинальная мощность коробки передач (кВт) должна соответствовать или превосходить мощность двигателя для плавной работы. Слабая коробка передач может снизить эффективность и повредить надежности системы. Это может привести к частому обслуживанию и неожиданным простоям.

Почему важны скоростные соотношения

Соотношение скорости играет решающую роль в выборе коробки передач. Коэффициенты передачи может быть от 1,25 до 450, в зависимости от модели. Это позволяет тонко настраивать скорость выхода для удовлетворения конкретных потребностей приложения. Такие системы, как робототехника и автоматизированные конвейеры, требуют точного контроля скорости, достигаемого с помощью точно установленных отношений передач. Конструкция останавливает внезапные запуски и остановки, поддерживая стабильное ускорение и замедление. Таким образом, он улучшает точность и рабочую гладкость.

Почему обслуживание является ключевой частью выбора коробка передач?

Функции, которые делают исправления легкими

Единоредукторная спиральная коробка передач с простым обслуживанием поддерживает плавную работу и низкие затраты. Его модульная структура и доступные компоненты делают рутинные проверки и замену деталей быстрыми и простыми. Многие модели имеют системы охлаждения и смазки. Они сохраняют внутренние части прохладными и уменьшают износ во время тяжелой работы. Сильные уплотнения блокируют пыль, воду и грязь. Это помогает коробке передач оставаться надежной в сложных промышленных условиях. Эти практические варианты конструкции уменьшают неожиданное время простоя и продлевают срок службы. Они также спасают предприятия от дорогостоящего ремонта или замены. Это обеспечивает стабильную эффективность с меньшим количеством проблем с обслуживанием.

Что искать в долгосрочной перспективе коробка передачэс

Коробка передач’ Срок службы зависит от его качества строительства. Коробки передач с закрепленными зубами передач класса 6 демонстрируют продленный срок службы, даже в условиях непрерывной работы. Профили передач, оптимизированные для шума, помогают уменьшить вибрации и обеспечить стабильную работу. Проверьте защиту от элементов. Корпусы с рейтингом IP65 обеспечивают надежную защиту от проникновения пыли и водного распыления, что делает их идеальными для суровых сред. Эти корпусы делают коробки передач подходящими для суровых условий, включая наружные и пыльные промышленные условия.

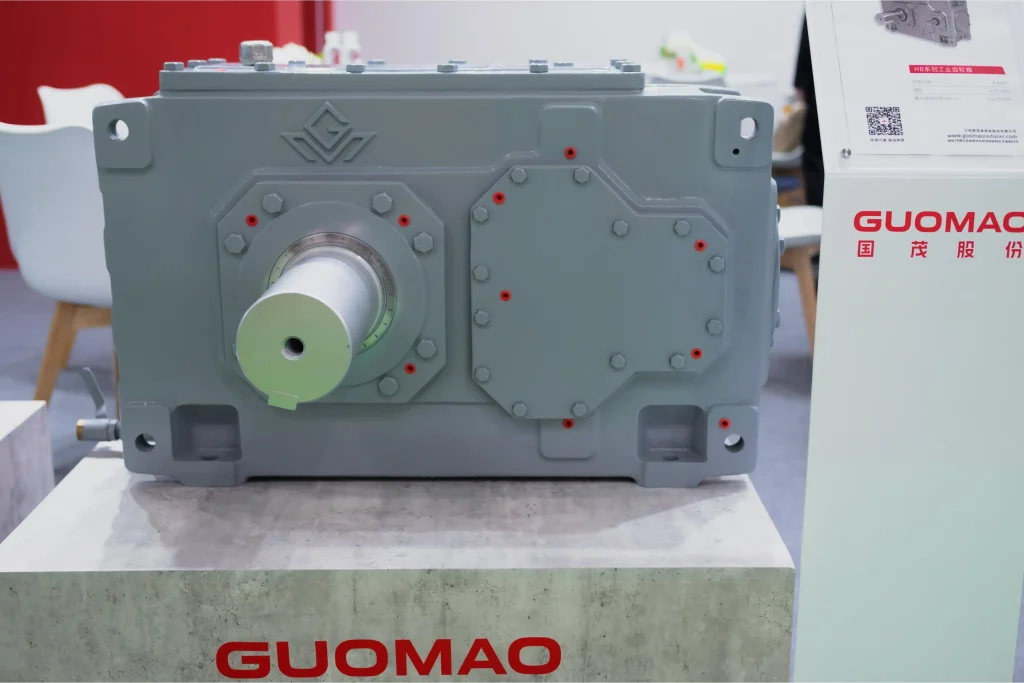

Почему выбрать Guomao для вашего единого сокращения спирального коробка передач Потребности?

Наше обещание качества и Развитые Инженерия

Guomao привержена передовой инженерии и строгим стандартам качества, особенно для винтовых коробок передач с одной редукцией. Мы стремимся к точному производству и строгим стандартам качества. Они изготовлены из сильной низкоуглеродной сплавной стали. Передачи получают процессы углевания и гашения, чтобы получить верхнюю твердость и прочность поверхности. Твердость поверхности зуба достигает 58-62 HRC, что гарантирует большую долговечность при тяжелых нагрузках. Поверхности углеродированных и гашенных передач обеспечивают сильную износостойкость, поддерживая продленный срок службы коробки передач. Наши одноступенчатые спиральные коробки передач достигают 98% эффективности. Это представляет собой исключительную производительность в широком спектре отраслей, включая производственный и энергетический секторы.

Проверка Guomao’ с Двойная спиральная передача Tech

Ключевые преимущества Guomao’ с двойная спиральная конструкция передач

Гуомао’ Технология двойной спиральной передачи предлагает значительный прогресс по сравнению с обычными системами передач. Он решает общие проблемы, встречающиеся в традиционных системах передач, такие как осиевая тяга и неравномерное распределение нагрузки. Эта конструкция уменьшает осиевую тягу и обеспечивает стабильную сетку передач во время работы с высокой нагрузкой. Наша жесткая обработка поверхности зуба повышает точность передачи и снижает рабочий шум. Двойная спиральная настройка делает сетку передач более гладкой. Это приводит к снижению износа при длительной эксплуатации. Кроме того, это’ С высокой адаптивностью. Модульная архитектура поддерживает широкий спектр форматов установки, включая конфигурации, установленные на ноги и фланцы. Такая конструкция обеспечивает надежную работу с минимальной сложностью.

Как Guomao обеспечивает надежную надежность в каждом продукте

Надежность является основной ценностью инженерной философии Guomao. Каждая коробка передач проходит строгие процедуры контроля качества в соответствии с международными стандартами. Они соответствуют глобальным стандартам. Например, наши специальные редукторы серии EXTR оснащены системами автоматической защиты, такими как контроль давления масла и температуры. Это гарантирует безопасную и надежную работу коробки передач в различных условиях. Кроме того, система смазки и охлаждения с принудительной циркуляцией повышает долговечность, поддерживая оптимальные тепловые условия. Процесс сборки поддерживает строгие допуски, обеспечивая высокую точность и минимальные сбои в эксплуатации. Твоя коробка передач длится дольше.

Подключение двигателей с Guomao коробка передачэс

Guomao обеспечивает оптимальную совместимость между двигателями и коробками передач. Наши одноредуктивные спиральные коробки передач работают со всеми видами двигателей. Гибкие конфигурации входного вала легко обрабатывают скорости до 1500 об/мин. Это гарантирует беспрепятственную интеграцию с различными двигательными системами и сценариями использования. Мы предлагаем варианты установки, такие как конфигурации B5, установленные на фланце или на ногу. Это обеспечивает высокую эффективность передачи и низкий уровень шума последовательно.

Часто задаваемые вопросы

В: Что’ с так хорошо о одной редукции спиральной коробки передач?

О: Они обеспечивают эффективность передачи до 98% и работают тихо из-за их конструкции спиральной передачи, высокой нагрузочной способности и широкой промышленной применимости.

В: Как я могу держать мою коробку передач в работе дольше?

A: Регулярно проверяйте уровни смазки и контролируйте давление и температуру масла, когда это применимо. Очистите снаружи. Проверьте на износ.

В: Могу ли я корректировать Соотношение скорости в моей коробке передач?

О: Да. Многие коробки передач позволяют выбрать коэффициент передачи от 1,25 до 450. Это зависит от вашей работы.

В: Почему спиральные коробки передач с одной редукцией настолько эффективны?

A: Угольные зубы держать передачи тесно связаны. Это дает вам до 98% эффективности и меньше шума.

В: Как я могу выбрать правильная коробка передач с одной редукцией для моей приложение?

О: Посмотрите на входную мощность (кВт), потребности в крутящем моменте (кНм), соотношение скоростей и то, что требует ваша работа.