Что делает планетарные редукторы редукторов необходимыми для современных двигателей?

Основные особенности планетарных редукторов

Планетарные редукторы передач являются жизненно важными компонентами в передовых промышленных машинах. Они используют сложную планетарную систему передачи, с планетарными передачами, вращающимися вокруг центральной солнечной передачи внутри внешней кольцевой передачи. Эта конфигурация обеспечивает надежное и эффективное распределение энергии. Их компактная конструкция выравнивает входные и выходные валы, оптимизируя использование пространства. Они обеспечивают высокие коэффициенты снижения, такие как 1:87 для одного этапа, с большими коэффициентами в многоступенчатых установках. Например, кран на строительной площадке в Техасе использовал свою экономичную конструкцию для эффективной эксплуатации.

Эти редукторы обеспечивают плавную, низкую производительность шума. Механизм циклоидной коробки приводит в действие несколько зубов одновременно, минимизируя вибрацию и звук. Построенные из прочной подшипниковой стали, они предлагают долгосрочную надежность. Их модульная структура упрощает сборку, демонтаж и обслуживание. Смешатель на заводе в Огайо работал тихо в течение многих лет, используя один.

Преимущества использования планетарных редукторов в двигателях

Планетарные редукторы значительно повышают производительность двигателя. Они обеспечивают эффективность передачи электроэнергии выше 90%, снижая потери энергии и поддерживая устойчивую работу. Их компактный размер легко интегрируется в двигательные системы, требуя минимальных модификаций. Калифорнийская роботизированная рука включила одну, аккуратно вписываясь в ее рамку.

Они отличаются в обращении с высоким крутящим моментом и сопротивляются тяжелым нагрузкам и ударам. Это делает их идеальными для приложений с частыми запусками, остановками или изменениями направления. Их прочная конструкция обеспечивает долговечность в суровых условиях. Флоридское морское судно использовало их в своем двигателе, выдерживая коррозионные условия соленой воды.

Как инновации повышают эффективность планетарных редукторов?

Роль материального прогресса в инновациях

Передовые материалы повышают производительность планетарного редуктора. Высокопрочные сплавные стали образуют прочные передачи, обеспечивая долговечность. Процессы, такие как углевание и гашение, затверждают зубы передач до HRC58-62, снижая износ и повышая эффективность. Дорожный ролик Джорджии полагался на эти передачи для устойчивой производительности.

Специализированные смазочные материалы, предназначенные для экстремальных условий, повышают надежность. Они обеспечивают плавную работу при тяжелых нагрузках или изменениях температуры. Буровая установка на Аляске использовала такие смазочные материалы, предотвращая сбои передач в условиях ниже нуля.

Усовершенствованные методы проектирования для улучшения производительности

Инновационные методы конструкции оптимизируют функциональность редуктора. Спирасные планеты и солнечные передачи обеспечивают точную, тихую передачу энергии. Двойно поддерживаемые игольные подшипники в планетарных передачах обеспечивают стабильность и прочность. Робот из Мичигана достиг высокой точности с помощью этих передач.

Настройчивые соотношения скорости позволяют адаптировать решения для конкретных приложений, обеспечивая оптимальную производительность. Нью-Йоркская пищевая смешилка использовала индивидуальное соотношение для последовательной обработки теста.

Влияние точного производства на долговечность и функциональность

Высокоточное производство обеспечивает превосходство редуктора. Точная шлифовка передач достигает идеального соединения сеток, минимизируя износ. Соблюдение стандартов ISO9001 поддерживает последовательное качество. Невадский кран работал надежно в пыльных условиях с помощью одного.

Соответствие IP65 защищает от проникновения пыли и воды, что делает их подходящими для сложных условий. Орегонское морское судно поддерживало производительность в влажных условиях с одним.

Почему планетарные редукторы имеют решающее значение для высокопроизводительных двигателей?

Применение планетарных редукторов передач в сценариях высокого крутящего момента

Планетарные редукторы отличаются в приложениях с высоким крутящим моментом, распределяя крутящий момент равномерно через их надежную конструкцию. Они используются в дорожных роликах, морских двигателях, башенных кранах и буровых установках, доставляющих до 850000 кНм. Чикагский башенный кран легко поднимал тяжелые стальные балки с помощью одного.

Они необходимы для смешивания таких приложений, как дробление асфальта или породы, где стабильный крутящий момент имеет решающее значение. Аризонская карьерная дробилка работала надежно весь день, используя одну.

Как планетарные редукторы передач улучшают скорость и точность двигателя

Эти редукторы позволяют точно управлять скоростью с коэффициентами от 3,4 до 2500, что идеально подходит для тонкой настройки производительности. Эта точность подходит для робототехники и аэрокосмических приложений, требующих точного позиционирования. Бостонская роботизированная рука достигла точности с помощью одного.

Их компактная планетарная конструкция уменьшает воздействие, обеспечивая повторяемость при выполнении точных задач. Техасский аэрокосмический инструмент сохранял последовательную точность на протяжении многих лет.

Что устанавливает Guomao’ с планетарные редукторы передач помимо конкурентов?

Обзор Guomao’ экспертизы в области планетарных редукторов

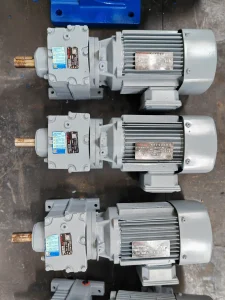

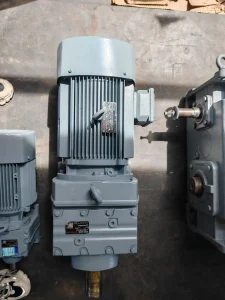

Guomao является лидером в производстве планетарных редукторов, управляемых инновациями, точностью и строгим контролем качества. Наш портфель включает циклоидные редукторы передач, цилиндрические редукторы передач и инженерные планетарные редукторы, изготовленные из высококачественных материалов и передовых технологий для долговечности и эффективности. Верфь в Вирджинии использовала наши редукторы для надежных морских операций.

Наши редукторы используют планетарную передачу, с планетарными передачами, вращающимися вокруг солнечной передачи в кольцевой передаче, обеспечивая компактную, эффективную передачу крутящего момента. Постоянные улучшения уменьшают шум, повышают прочность и увеличивают нагрузку. Завод в Иллинойсе оценил его низкий уровень шума.

Особенность конкретных продуктов: Guomao GPN серии планетарных редукторов

Редуктор планетарных передач серии Guomao GPN разработан для двигателей, требующих точности и прочности. Он имеет спиральную планету и солнечные передачи, затвержденные до HRC58-62 для эффективной передачи энергии. Полнодополнительные игольные подшипники обеспечивают жесткость и плавную работу при тяжелых нагрузках. Робот из Колорадо плавно обрабатывал тяжелые компоненты с одним.

Соответствие IP65 защищает от пыли и воды, идеально подходит для строительства или морских условий. Луизианский дорожный ролик работал надежно в влажных, грязных условиях, используя один.

Особенности и преимущества Guomao’ серии GPN для современных двигателей

Серия GPN предлагает передовые возможности для двигательных приложений:

- Эффективная передача энергииКонструкция передач типа S повышает энергоэффективность и обеспечивает последовательный крутящий момент.

- Компактная формаВыровненные входные и выходные валы минимизируют потребности в пространстве.

- Прочное строительство: высокопрочные сплавные стали с карбуризацией обеспечивают долговечность.

- Индивидуальные соотношенияКоэффициенты от 3,4 до 2500 удовлетворяют различным потребностям.

- Тихое исполнение: спиральные передачи уменьшают вибрацию для снижения шума.

- Упрощенное обслуживаниеМодульная конструкция упрощает обслуживание. Продовольственный завод в штате Орегон использовал серию GPN в миксере, получая выгоду от тихой работы и простого обслуживания.

Отзывы клиентов и реальные приложения продуктов Guomao

Гуомао’ редукторы заслуживают похвалы во всех отраслях промышленности. Техасские дорожные ролики и краны подчеркивают свою долговечность в тепле и пыли. Морские приложения Флориды похваляют свою устойчивость в соляных условиях, обрабатывающий крутящий момент до 850000 кНм. Асфальтовые смешители Джорджии ценят свою стабильную мощность. Калифорнийские аэрокосмические клиенты хваляют их точность в полупроводниковом оборудовании. Клиенты ценят их беспрепятственную интеграцию двигателя, повышая эффективность.

Часто задаваемые вопросы

В: Какие рабочие места больше всего нуждаются в планетарных редукторах?

Ответ: Строительство, морская, робототехника, аэрокосмическая, пищевая переработка и тяжелые машины получают выгоду от их высокого крутящего момента и компактной конструкции.

В: Как планетарные редукторы передач делают двигатели лучше?

A: Они улучшают эффективность и уменьшают износ с высокими коэффициентами снижения, обеспечивая надежную работу.

В: Как вы держите редуктор планетарной передачи длительным?

A: Используйте соответствующие смазочные материалы и периодически проверяйте выравнивание или повреждение.

В: Можете ли вы настроить редукторы планетарных передач для специальных работ?

A: Да, индивидуальные соотношения и покрытия могут быть адаптированы к уникальным требованиям.

В: Что такое редуктор планетарного снаряжения?

A: Компактное устройство с солнечной передачей, планетарными передачами и кольцевыми передачами, предназначенное для эффективной передачи крутящего момента.