Introducción: Comprender los beneficios de las cajas de engranajes helicoidales de dos etapas en aplicaciones pesadas

Las máquinas industriales se acercan al futuro. Los sistemas de poder son el corazón y el alma. Mantienen las cosas funcionando sin problemas y de forma constante. Las cajas de cambios helicoidales de dos etapas son las verdaderas estrellas aquí. Manivelan un enorme par, ralentizan las cosas y entregan energía con una precisión afilada al láser. Desde pozos mineros hasta sitios de construcción, estas cajas de cambios son galletas resistentes. Ellos’ es una necesidad para las industrias que persiguen máquinas fuertes y rápidas que nunca se rinden.

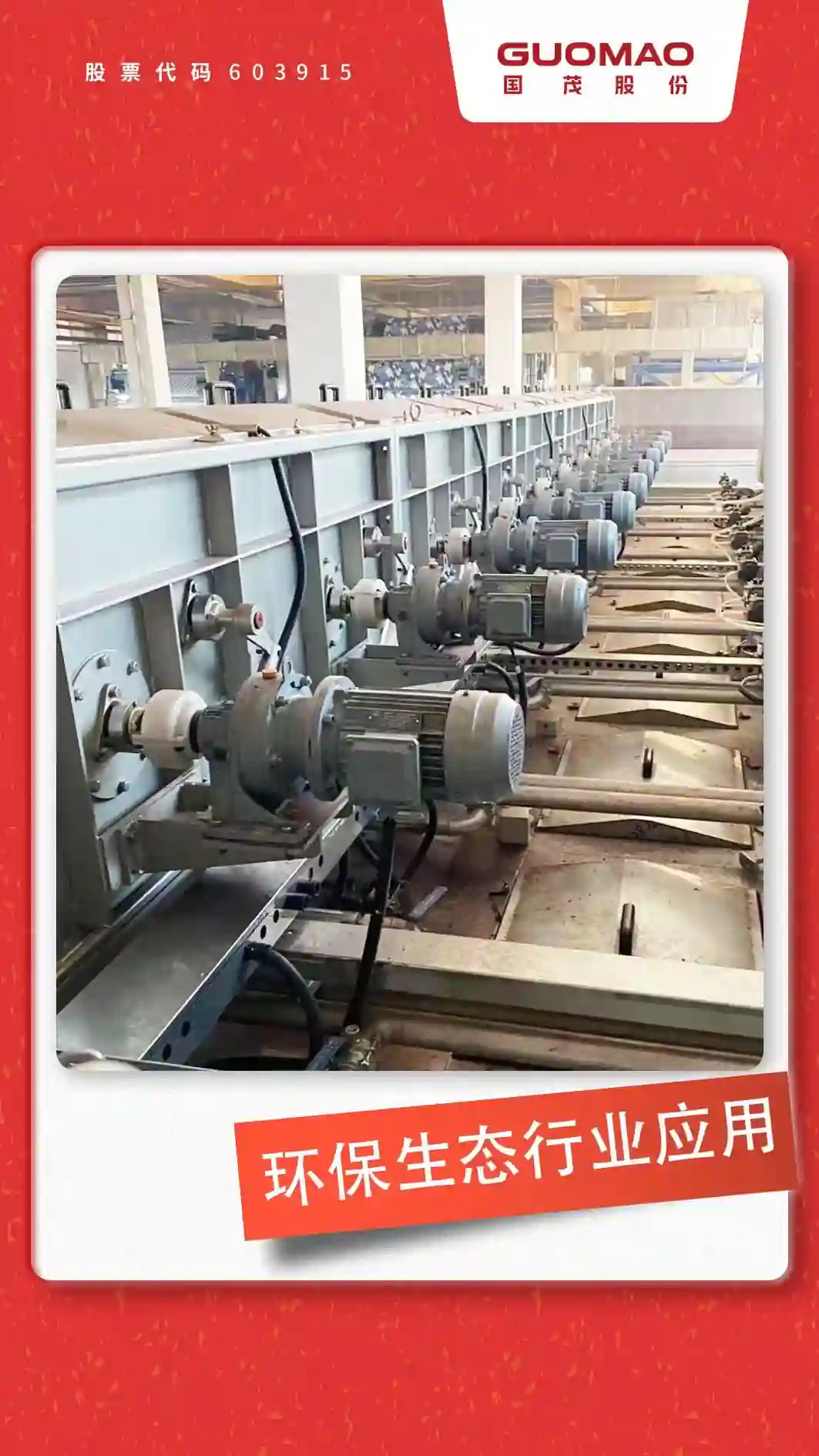

Este blog se sumerge en por qué las cajas de engranajes helicoidales de dos etapas son increíbles para trabajos pesados. Nosotros’ ll desempaquetar cómo marcan y por qué Guomao’ Los diseños inteligentes los hacen una opción superior. Además, nosotros’ Lanzará consejos para elegir la caja de cambios perfecta para sobrecargar su maquinaria.

¿Qué son las cajas de engranajes helicoidales de dos etapas?

Las cajas de cambios helicoidales de dos etapas son pequeñas centrales eléctricas elegantes. Utilizan dos conjuntos de engranajes helicoidales para disminuir la velocidad y aumentar el par. Hechos para tareas pesadas, manejan cargas de monstruos como campeones. La primera etapa reduce el ritmo. La segunda etapa bombea el par hacia arriba.

Los engranajes’ Los dientes inclinados los hacen súper silenciosos. También superan a otros tipos de engranajes. Esto hace que las cajas de cambios helicoidales de dos etapas sean perfectas para trabajos que requieren una acción constante y fiable.

¿Cómo funcionan las cajas de engranajes helicoidales de dos etapas?

Estas cajas de cambios mezclan la energía del motor a la máquina. Reducen la velocidad mientras absorben el par. Aquí’ El acuerdo:

- Primera etapaEl motor gira el engranaje solar. Empuja los engranajes planetarios, que se bloquean con el engranaje de anillo. Esto vuelve a marcar la velocidad y establece la potencia para el siguiente bit.

- Segunda etapaLa potencia salta a otro conjunto de engranajes planetarios. Esto ralentiza las cosas aún más y manivela el par más alto.

Dos etapas permiten a estas cajas de cambios empaquetar un par masivo en una pequeña caja. Eso’ s una gran victoria para espacios estrechos donde el poder puede’ t tomar una siesta.

Ventajas clave de las cajas de engranajes helicoidales de dos etapas para aplicaciones pesadas

Alta capacidad de par y eficiencia

Las cajas de cambios helicoidales de dos etapas aportan músculo serio. Manejan torsión gigante para máquinas pesadas. Su pequeño tamaño se adapta a puntos acogedores sin perder la cremallera. Guomao construye estas cajas de cambios para un rendimiento superior. Mantienen las máquinas zumbido fuerte en las condiciones más salvajes, sin preocupaciones.

Diseño compacto con beneficios de ahorro de espacio

El espacio es limitado en muchas industrias. Las máquinas necesitan presionarse en cómodas esquinas sin perder energía. Las cajas de cambios helicoidales de dos etapas proporcionan un gran par en un pequeño paquete. Ellos’ Perfecto para robótica, líneas de fábrica o minería, donde el espacio vale su peso en oro.

Guomao’ Las cajas de cambios de S mantienen el flujo de energía sin problemas mientras ahorran espacio para otros bits de la máquina. Es’ s una solución inteligente para configuraciones empaquetadas.

Reducción de ruido y vibraciones para mejores entornos operativos

Las máquinas fuertes son un dolor. Las cajas de cambios helicoidales de dos etapas calman las cosas. Sus engranajes inclinados se unen suavemente, cortando los casquillos y los ruidos. Esto es un gran problema para lugares como hospitales o fábricas donde el ruido es un no-no.

Guomao’ cajas de cambios, como el Motor helicoidal de eje paralelo de la serie GF, Utilizar materiales de primera calidad. Mantienen silencio y estabilidad, haciendo que el trabajo sea más cómodo y ayudando a que las máquinas duren más tiempo.

Durabilidad y longevidad en entornos industriales duros

Los trabajos pesados son brutales. Las cajas de engranajes enfrentan calor ardiente, aire polvoriento y condiciones húmedas. Las cajas de cambios helicoidales de dos etapas se construyen como tanques. Los materiales de primera clase les permiten prosperar en lugares difíciles sin parpadear.

Guomao’ Las cajas de cambios están hechas para quedarse alrededor. Utilizamos materiales de alta calidad y artesanía inteligente para asegurarnos de que se mantengan altos en condiciones locas.

Aplicaciones de cajas de engranajes helicoidales de dos etapas en industrias pesadas

Estas cajas de cambios iluminan industrias difíciles. Traen potencia y fiabilidad a los trabajos más difíciles.

Minería y extracción

Los equipos de minería como trituradoras y transportadores necesitan un par monstruoso. Las cajas de cambios helicoidales de dos etapas lo entregan en un paquete pequeño. Manejan cargas pesadas todo el día, lo que los convierte en un go-to para conciertos de minería.

Maquinaria de construcción

Las grúas, excavadoras y cargadoras necesitan sistemas de energía robustos. Cajas de cambios helicoidales de dos etapas Mantenga las cosas chugging suavemente. Ellos’ lo suficientemente resistente para las tareas de construcción más pesadas, manos abajo.

Sistemas de fabricación e industriales

Prensas pesadas, molinos y mezcladores anhelan cajas de cambios fiables. Guomao’ Las cajas de cambios helicoidales de dos etapas abordan cargas altas sin un hipo. Ellos’ re confiado en fábricas donde el poder y la fiabilidad gobiernan.

Equipo Marino y Offshore

El equipo marino, como los cabrestantes y los sistemas de propulsión, se enfrenta a mares ásperos. Las cajas de cambios helicoidales de dos etapas son compactas y poderosas, perfectas para trabajos marítimos donde el espacio y la resistencia lo son todo.

Cómo elegir la caja de engranajes helicoidal de dos etapas adecuada para su aplicación pesada

Elegir la caja de cambios adecuada es clave para sacudir su maquinaria. Aquí’ s el lowdown en clavarlo.

Evaluar los requisitos de par y velocidad

Coincide con la caja de cambios’ s par y velocidad a su máquina’ necesidades. Las cajas de cambios helicoidales de dos etapas se pueden ajustar para niveles de potencia específicos. Esto los hace encajar en su sistema como un guante acogedor.

Selección de materiales para la durabilidad

Los materiales importan mucho. Para entornos ásperos, elija cajas de cambios con piezas a prueba de oxidación. Esto los mantiene fuertes durante años, incluso en lugares difíciles.

Consideraciones de instalación

Su caja de cambios necesita moverse con su máquina. Guomao ofrece opciones de montaje flexivo. Esto hace que la configuración sea rápida y reduce el tiempo de inactividad durante actualizaciones o intercambios.

Guomao Compañía y Producto

Guomao es un golpeador pesado en las cajas de cambios. Nos especializamos en cajas de cambios helicoidales de dos etapas para trabajos pesados. Con más de 20 años en el negocio, ofrecemos soluciones resistentes, rápidas y de alto par para la minería, la construcción y más.

Nosotros’ Todo sobre personalización. ¿Necesitas relaciones de engranajes o par específicos? ¿Espacios estrechos? Guomao trabaja con usted para crear la caja de cambios perfecta, cada vez.

Preguntas frecuentes

P: ¿Qué industrias se benefician más de las cajas de cambios helicoidales de dos etapas?

R: Las industrias minera, de construcción, de fabricación y marina las excavan. Su gran par y resistencia los hacen increíbles para trabajos difíciles.

P: ¿Cómo se comparan las cajas de cambios helicoidales de dos etapas con las cajas de cambios de una sola etapa?

R: Los de dos etapas empaquetan más par y cremallera. Ellos’ mejor para tareas pesadas, mientras que las de una sola etapa se adaptan a conciertos más ligeros.

P: ¿Qué mantenimiento se requiere para las cajas de cambios helicoidales de dos etapas?

R: Los controles regulares del aceite, las miradas de desgaste y la alineación adecuada los mantienen zumbidos. El mantenimiento es fácil, pero súper clave.

P: ¿Se pueden personalizar las cajas de cambios helicoidales de dos etapas para aplicaciones específicas?

R: Apuesta. Guomao los adapta a sus necesidades, como relaciones de engranajes específicas, par o configuraciones de montaje.

P: ¿Cuáles son las señales de que una caja de cambios helicoidal de dos etapas necesita servicio o reemplazo?

R: Ruidos fuertes, temblores, sobrecalentamiento o acción más débil significan que’ s tiempo para un chequeo o intercambio.