¿Cuáles son las causas comunes de ruido anormal en los reductores helicoidales biselados?

¿Cómo afecta la lubricación el rendimiento de los reductores helicoidales biselos?

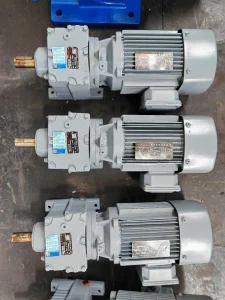

Mantener la lubricación intacta es el secreto para que los reductores helicoidales biselados funcionen en su mejor momento. Los reductores helicoidales biselados dependen de la interacción en marcha para trabajar en su mejor momento y la lubricación adecuada tiene un papel importante en la disminución de la fricción y el desgaste de los dientes del engranaje. Los lubricantes de muesca garantizan que las piezas móviles se deslizan sin esfuerzo, eliminando el riesgo de estrés mecánico y sobrecalentamiento. Llevar El MOTOR Con Engranaje Helicoidal De la serie GR como ejemplo, es un buen ejemplo de bajo ruido y alta eficiencia de transmisión debido a su diseño preciso y sistemas de lubricación efectivos. Si un sistema está bien diseñado internamente y funciona de manera efectiva en otros aspectos, pero no obtiene una lubricación adecuada, esto puede conducir a una falla prematura ya que sus componentes no se deslizan suavemente con el tiempo.

¿Qué sucede cuando la lubricación falla en reductores helicoidales biselos?

La falla de la lubricación puede afectar en gran medida los reductores de engranajes helicoidales, ya que puede provocar más fricción entre los engranajes durante una deficiencia de lubricante o desgaste, generando así un exceso de calor, facilitando el desgaste y perdiendo la resistencia de los componentes del engranaje. Eventualmente puede conducir a la desalineación, lo que causa vibración y ruido anormal durante la operación. Especialmente afecta los componentes de precisión. En condiciones severas, el fenómeno puede conducir a todo el bloqueo del sistema y puede ser costoso de reparar o reemplazar.

¿Hay otros factores que contribuyen al ruido anormal en los reductores helicoidales biselos?

Además de los problemas con la lubricación, algunos factores pueden causar ruidos extraños en los reductores helicoidales biselados. Un problema común es que la desalineación da como resultado patrones de contacto desiguales y ruido durante el uso. Además, los niveles de ruido se pueden combinar mediante rodamientos fuera de lugar o métodos de instalación defectuosos. Las desviaciones de la especificación de diseño o los defectos de fabricación también pueden contribuir a la excentricidad de la malla de engranaje, lo que resulta en un mayor ruido. El mantenimiento y la adhesión al proceso de instalación deben llevarse a cabo para reducir los riesgos.

¿Cómo puede la mala lubricación provocar daños en el engranaje en los reductores helicoidales biselados?

El papel de la lubricación adecuada para prevenir el desgaste

La buena lubricación crea una película de amortiguación entre los metales para evitar el contacto durante los procesos de servicio pesado, extendiendo la vida útil de los reductores helicoidales biselados, como el Serie GK Motor con engranaje helicoidal, diseñado con características avanzadas para proporcionar el mejor rendimiento cuando se combina con buenos lubricantes. Sin protección contra la corrosión, la degradación del material se produce más rápidamente, lo que lleva a problemas como la puntuación, las picaduras o incluso la falla completa de los componentes del engranaje.

La conexión entre fricción y ruido en reductores helicoidales biselados

La lubricación insuficiente que conduce a la fricción está estrechamente conectada con la creación de sonidos inusuales en el proceso de operación del sistema. Cuando los niveles de fricción aumentan dentro del mecanismo en sí, se producen vibraciones, que se traducen en ruido. Esto no solo afecta la eficiencia, sino que también señala el daño potencial dentro del reductor. Los lubricantes especiales también ayudan a reducir la fricción de manera eficiente al mantener un grosor de película óptimo entre los componentes móviles.

Signos que indican problemas de lubricación en su reductor helicoidal bisel

Estas señales de advertencia temprana pueden indicar problemas de lubricación antes de que ocurran, como cuando las piezas ya se calientan mientras se ejecutan, lo que puede indicar que la lubricación es baja o ninguna. Los sonidos de chillido y molido también pueden indicar que hay poco lubricante que fluye o que algo está sucio en las máquinas.

¿Cómo prevenir el ruido anormal causado por problemas de lubricación?

Las mejores prácticas para mantener una lubricación óptima

El rendimiento del reductor helicoidal más importante para biselarse es la naturaleza del lubricante a seleccionar, ya que debe poder responder a las demandas de operación y diseño individuales del reductor en cuestión. Los lubricantes adecuados reducen el desgaste y la fricción y promueven el funcionamiento suave de los engranajes. Además, al seleccionar un lubricante para proporcionar un rendimiento óptimo, debe evaluarse en términos de temperaturas de funcionamiento, capacidad de transporte de carga y condiciones ambientales. La mayoría prefiere los aceites porque pueden proporcionar el más alto grosor en temperaturas variables. Sin embargo, los aceites minerales funcionan bien para los usos típicos.

La importancia de las inspecciones y reparaciones oportunas

Las inspecciones de rutina son necesarias en la detección de problemas de lubricación lo suficientemente temprano como para que no se conviertan en problemas monumentales más adelante. Los técnicos, tras la inspección, deben verificar cualquier cambio en los lubricantes, como el color o la consistencia, lo que puede indicar la contaminación o el desgaste. Los sonidos de molienda y chillidos son un signo de falta de lubricación en las piezas o engranajes que no están alineados correctamente. Corregir estos problemas con el mantenimiento o incluso cambiar el lubricante evitará el desgaste en piezas críticas.

¿Por qué elegir el reductor helicoidal biselante de Guomao para un rendimiento confiable?

Nuestra experiencia en la fabricación de reductores helicoidales de bisel de alta calidad

Características de diseño avanzadas que garantizan una operación tranquila

Las cajas de cambios helicoidales biselales de Guomao están meticulosamente elaboradas para un rendimiento suave con ingeniería de precisión en nuestro núcleo. El uso de engranajes helicoidales y biselos de muesca en nuestro diseño asegura malla precisa y un rendimiento óptimo. Llevar el Caja de cambios industrial H-paralela como ejemplo, logra la precisión de los dientes a través de la mano de obra meticulosa y la tecnología de vanguardia para niveles de ruido reducidos y una mayor eficiencia. A través de enfoques de diseño y atención al detalle en las prácticas de fabricación, Guomao garantiza que nuestras cajas de cambios helicoidales biselas funcionen sin problemas en varios entornos industriales.

Materiales superiores e ingeniería de precisión para la durabilidad

Los reductores helicoidales biselados de Guomao tienen una resistencia superior debido a la razón por la cual la materia prima de alto grado junto con la precisión en la ingeniería. Los engranajes se fabrican a partir de acero de aleación baja en carbono que se carbura y se apaga con fuerza. Esto mejora su fuerza bajo un peso pesado y pone menos desgaste en usos extendidos. Además, el proceso de ensamblaje de Guomao asegura que las piezas se fijen con la máxima precisión y, por lo tanto, los productos proporcionados son duraderos y confiables.

Cómo los productos de Guomao abordan desafíos de lubricación comunes

Los reductores helicoidales biselos de Guomao vienen con mecanismos incorporados que se crean específicamente para mejorar el manejo de la lubricación de manera eficiente. Proporcionan una distribución de lubricante sobre los componentes móviles para producir fricción y reducción del desgaste. El motor de engranaje helicoidal de la serie GR es uno de ello que funciona perfectamente con su eficiencia de transmisión y menos salida de ruido debido a las arreglos precisos de ingeniería y lubricación eficiente. Dichos sistemas funcionan basados en proporcionar un grosor de película entre las superficies de los engranajes para evitar el sobrecalentamiento y prolongar la vida útil de los reductores.

Los clientes que optan por un reductor helicoidal de Guomao tienen la ventaja del matrimonio de tecnología innovadora con materiales resistentes y características planificadas con precisión que están específicamente diseñadas para cumplir con los requisitos de los entornos industriales contemporáneos.

Preguntas frecuentes sobre Reductor Helicoidal Bisel

P: ¿Qué es un reductor helicoidal de bisel?

R: Un reductor helicoidal biselado es un mecanismo de engranajes que combina la aplicación de engranajes biselos y engranajes helicoidales para transferir la potencia y el movimiento entre los ejes no paralelos. Proporcionan alto par y eficiencia en diseños compactos para aplicaciones industriales.

P: ¿Cuáles son las ventajas de los reductores helicoidales biselados?

R: Los reductores helicoidales de bisel aseguran una operación más suave, una mayor capacidad de torque y una mejor distribución de carga que las cajas de cambios convencionales. Su combinación de bisel y equipo helicoidal garantiza una transmisión de potencia eficiente con menos vibración y ruido.

P: ¿Dónde se usan comúnmente los reductores helicoidales biselales?

R: Los reductores helicoidales de bisel tienen un uso extenso en industrias como el automóvil, el equipo transportador, el manejo de materiales y la maquinaria de servicio pesado. Son ideales para los usos que requieren un par alto y reducciones de engranajes lisos y precisos.

P: ¿Cómo elijo el reductor helicoidal de bisel correcto?

R: Seleccionar el reductor helicoidal bisel correcto implica considerar el par requerido, la relación de reducción para la velocidad, la orientación del eje y la capacidad de carga. Seleccionar estos factores en función de las especificaciones del reductor garantiza el máximo rendimiento y durabilidad.