Planetary gearbox design and technology are evolving as industrial systems demand higher torque density, better precision, and longer service life. Modern planetary gearbox solutions are no longer viewed as isolated mechanical components but as integrated elements within complex drive systems that must balance performance, reliability, and lifecycle efficiency. Understanding these trends helps engineers and technical buyers make informed decisions when selecting gearboxes for demanding applications.

Planetary Gearbox Market Drivers Behind New Design and Technology Trends

Industrial Automation and Robotics Pushing Planetary Gearbox Performance Limits

The quick growth of industrial automation and robotics is changing planetary gearbox needs. Automated lines and robot setups depend on planetary gearboxes. They provide steady torque transfer, even motion handling, and reliable backlash patterns. Such needs push designers to adjust gear shapes and bearing setups. This supports high repeat accuracy during nonstop work.

Heavy-Duty and Mobile Equipment Demanding Higher Torque Density

Demand for high torque planetary gearboxes keeps rising in building tools, mining gear, and movable industrial machines. These uses need small gearboxes that handle big loads. They must resist jolts and uneven work cycles. So, current planetary gearbox design stresses an even load split among planets and tougher carriers. This boosts torque density without growing the full size.

Energy Efficiency and Lifecycle Cost Pressures in Industrial Gearbox Selection

Energy savings and full lifecycle costs now shape planetary gearbox choices more than before. Factory users check efficiency drops, heat buildup, and upkeep schedules. They do this along with torque ratings. Designs that cut power waste and stretch service time lower running costs. They also boost long-run system stability.

Planetary Gearbox Design Trends Shaping Modern Transmission Systems

High Torque Density Planetary Gearbox Design for Compact Installations

High torque density planetary gearbox design focuses on transmitting greater output torque within a limited installation space. Engineers achieve this by optimizing gear tooth contact, increasing the number of planet gears, and improving carrier rigidity. These design strategies are especially valuable in applications where space constraints and high load requirements coexist.

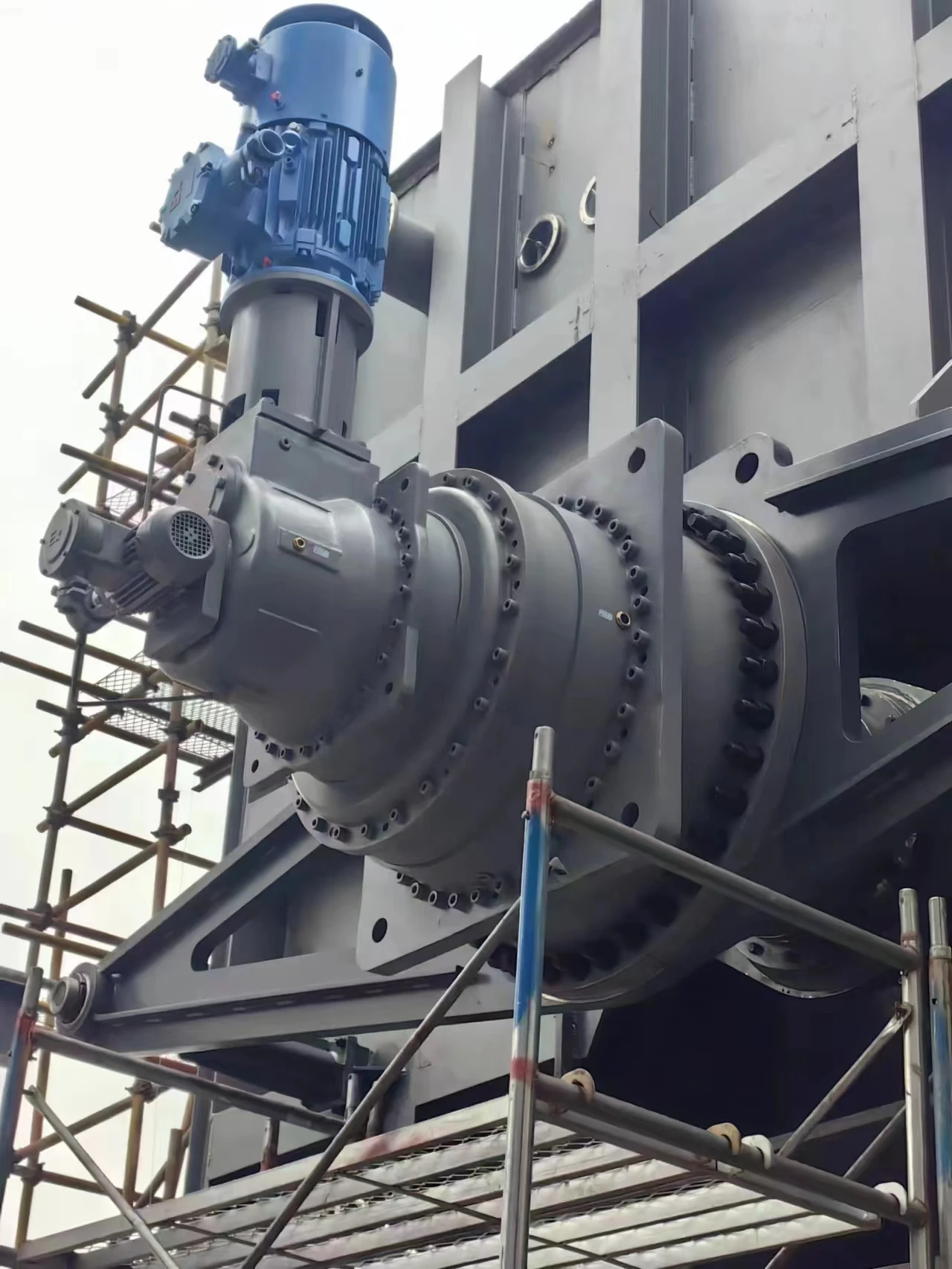

In heavy-duty industrial environments, this design philosophy is reflected in Guomao’s Ingeniería de la caja de cambios planetaria mecánica, which is developed for applications such as mixing equipment, construction machinery, and marine systems. Its compact planetary structure allows high torque transmission while maintaining structural stability under continuous or intermittent heavy loads.

Modular Planetary Gearbox Architecture for Flexible System Integration

The modular planetary gearbox build has turned into a major shift for easy system fitting. Such designs let gear levels, ratios, and mount choices mix well. This cuts wait time for custom fixes. The method aids both common and unusual setups. It keeps steady output traits.

Structural Optimization for Load Distribution and Fatigue Life

Structural tweaks matter a lot in growing planetary gearbox fatigue life. Better load spread over gears and bearings cuts local strain and shakes. Stronger housing stiffness and carrier builds add to even running. This holds true in uses with often-changing loads or strong jolts.

Advances in Planetary Gearbox Materials and Manufacturing Technology

Advanced Gear Materials Improving Strength and Wear Resistance

Planetary gearbox lasting power rests much on material choices. New alloy steels with set makeup are common now. They raise strength, wear hold, and fatigue action. These let planetary gearboxes run steadily under high-torque stress and hard work cycles.

Precision Heat Treatment and Gear Grinding Technologies

Planetary gearbox making leans more on exact heat treatment and gear grinding methods. Managed carburizing and quenching steps boost surface hardness. They keep core toughness intact. Careful gear grinding lifts tooth exactness and surface quality. This leads to easier meshing, less noise, and better transfer efficiency.

Manufacturing Consistency and Repeatability in Industrial Planetary Gearboxes

Maintaining steadiness is vital for the expected planetary gearbox output. Firm machining accuracy, set check steps, and guided assembly ensure each unit hits design marks. This sameness matters for factory users with many machines in lines or sites.

Planetary Gearbox Technology Trends in Reliability, Monitoring, and Maintenance

Design for Long Service Life in High-Load Planetary Gearbox Applications

Planetary gearbox dependability gets handled early in design. Bearing choices, service multipliers, and oil paths get tuned for long run times under set loads. These steps cut surprise stops and raise gear uptime.

Condition Monitoring Concepts in Modern Planetary Gearbox Systems

Planetary gearbox tech fits better with condition check plans now. Gearboxes stay mechanical, but their builds support shake checks, heat tracking, and oil state reviews. These steps let upkeep teams spot early wear signs. Then, they schedule fixes better.

Lubrication, Sealing, and Thermal Management Improvements

Oil handling and heat control gains aid the planetary gearbox’s long life a lot. Tuned oil flow keeps steady lube on gears and bearings. Better seals cut dirt entry risk. Good heat release holds even temps. This backs a smooth power send.

How Application Requirements Influence Planetary Gearbox Selection Trends

Precision Planetary Gearbox Trends for Robotics and Machine Tools

Precision planetary gearbox uses like robotics and machine tools stress low backlash, strong twist stiffness, and even motion. These needs shape design toward closer fits, firm housings, and well-paired gear levels. Precision planetary gearboxes allow exact placement and repeat motion in auto and fine gear.

Guomao’ s Reductor planetario de precisión fits these cases by design. It aids auto tools and special machines. The build focuses on set backlash, steady torque send, and a small fit with motor systems.

Heavy-Duty Planetary Gearbox Trends in Construction and Mining Equipment

Heavy-duty planetary gearbox picks center on torque power, jolt hold, and lasting strength. Gear in building, mining, and material work faces changing loads and rough spots. Strong housings, beefed-up gear levels, and sure bearing setups are musts here.

Custom Planetary Gearbox Solutions for Non-Standard Industrial Applications

Custom planetary gearbox fixes are needed more for unusual factory uses. When off-the-shelf types miss ratio, load, or fit needs, tailored builds work well. This shift shows the value of use-focused engineering and teamwork in picking gearboxes.

How Guomao Addresses Modern Planetary Gearbox Design and Technology Challenges

Engineering-Oriented Planetary Gearbox Design for High Torque and Compact Systems

Guomao builds planetary gearboxes with an engineering view of true work conditions. Our heavy-duty planetary gearbox options mix small builds with strong torque output. They ensure firm action in hard factory spots.

Manufacturing Capabilities Supporting Consistent Planetary Gearbox Quality

Making skills shape planetary gearbox dependability. We use guided machining, exact heat steps, and set assembly to give steady quality in every unit. This sameness backs expected output and long service.

Application-Based Planetary Gearbox Solutions Across Multiple Industries

Use-based design lets us match planetary gearbox traits to real system needs. We blend engineering review with making know-how. This aids many fields that want either a strong torque send or fine motion control.

Preguntas frecuentes

Q: Planetary Gearbox: Which brand is considered good for industrial applications?

A: A good planetary gearbox brand is defined by engineering capability, manufacturing consistency, and proven performance in real applications. Torque capacity, precision, service life, and technical support are key evaluation factors.

Q: Planetary Gearbox selection: How should torque and ratio be evaluated?

A: Planetary gearbox selection should start with the required output torque and speed ratio, followed by evaluation of duty cycle, shock loads, and installation conditions to ensure safe and reliable operation.

Q: Planetary Gearbox vs. other gearbox types: What are the main differences?

A: Planetary gearboxes distribute load across multiple gears, allowing higher torque density and a more compact design compared to many parallel shaft or worm gearbox types.

Q: Planetary Gearbox applications: Where are they most commonly used?

A: Planetary gearboxes see common use in robotics, auto systems, building machines, mixers, and heavy factory gear. This comes from their small size and high torque power.

Q: Custom Planetary Gearbox solutions: When are they necessary?

A: Custom planetary gearbox fixes are key when standard types fail on special needs like odd ratios, extreme loads, or unique fit limits.