Ventaja de alto par de la caja de engranajes helicoidal de 2 etapas en aplicaciones pesadas

Hoy’ En el mundo de la fábrica, las máquinas pesadas se enfrentan a grandes demandas: transportar cargas pesadas, funcionar sin parar y mantenerse resistentes bajo un estrés loco. Con las fábricas eléctricas y súper inteligentes, las necesidades de par están disparando. Una caja de cambios helicoidal de 2 etapas aumenta mucho aquí. Bombea el mega par sin necesidad de un engranaje voluminoso. Al mezclar dos etapas de engranajes, aumenta el par de una manera elegante y compacta, manteniendo las cosas con cremallera y eficiente.

Cómo las dobles etapas amplifican el par sin aumentar el tamaño

Las cajas de engranajes de una sola etapa golpean rápidamente una pared cuando se les pide una gran relación de reducción. Una configuración de 2 etapas divide el trabajo en dos conjuntos de engranajes. Este truco inteligente:

- Evita que los engranajes se vuelvan demasiado gruesos.

- Equilibra los aumentos de par con una carcasa ordenada.

- Proporciona la energía necesaria para trabajos difíciles.

Es’ como empaquetar un gran golpe en un paquete pequeño, perfecto para tareas pesadas.

Industrias exigentes que se benefician de un alto rendimiento de par

- MineríaLas trituradoras y transportadoras necesitan un par constante y alto para mover cosas pesadas.

- Acero y MetalurgíaLas laminadoras anhelan un par constante para el trabajo duro.

- Logística PortuariaGrúas y apiladores levantan contenedores sin hipos.

- Maquinaria de construcciónLos movimientos de tierra dependen de un par estable en lugares difíciles.

Diseño compacto de caja de engranajes helicoidal de 2 etapas para maquinaria pesada limitada por espacio

Las fábricas modernas aman ahorrar espacio. Las líneas de automatización, los robots y las configuraciones de producción ajustadas necesitan cajas de cambios poderosas que no’ t cerdo el suelo. Una caja de cambios helicoidal de 2 etapas es un campeón total para estos puntos, entregando gran potencia sin hacerse cargo.

Lograr altos índices de reducción en una huella mínima

Una caja de cambios de 2 etapas exprime altas relaciones de reducción en una pequeña carcasa. En lugar de engranajes gigantes, utiliza dos etapas para multiplicar el par. Esto permite a los fabricantes construir máquinas compactas que todavía tienen un impacto. Es’ Es como montar un motor monstruoso en un coche pequeño, poderoso pero inteligente en el espacio.

Disipación eficiente del calor en diseños compactos de caja de cambios

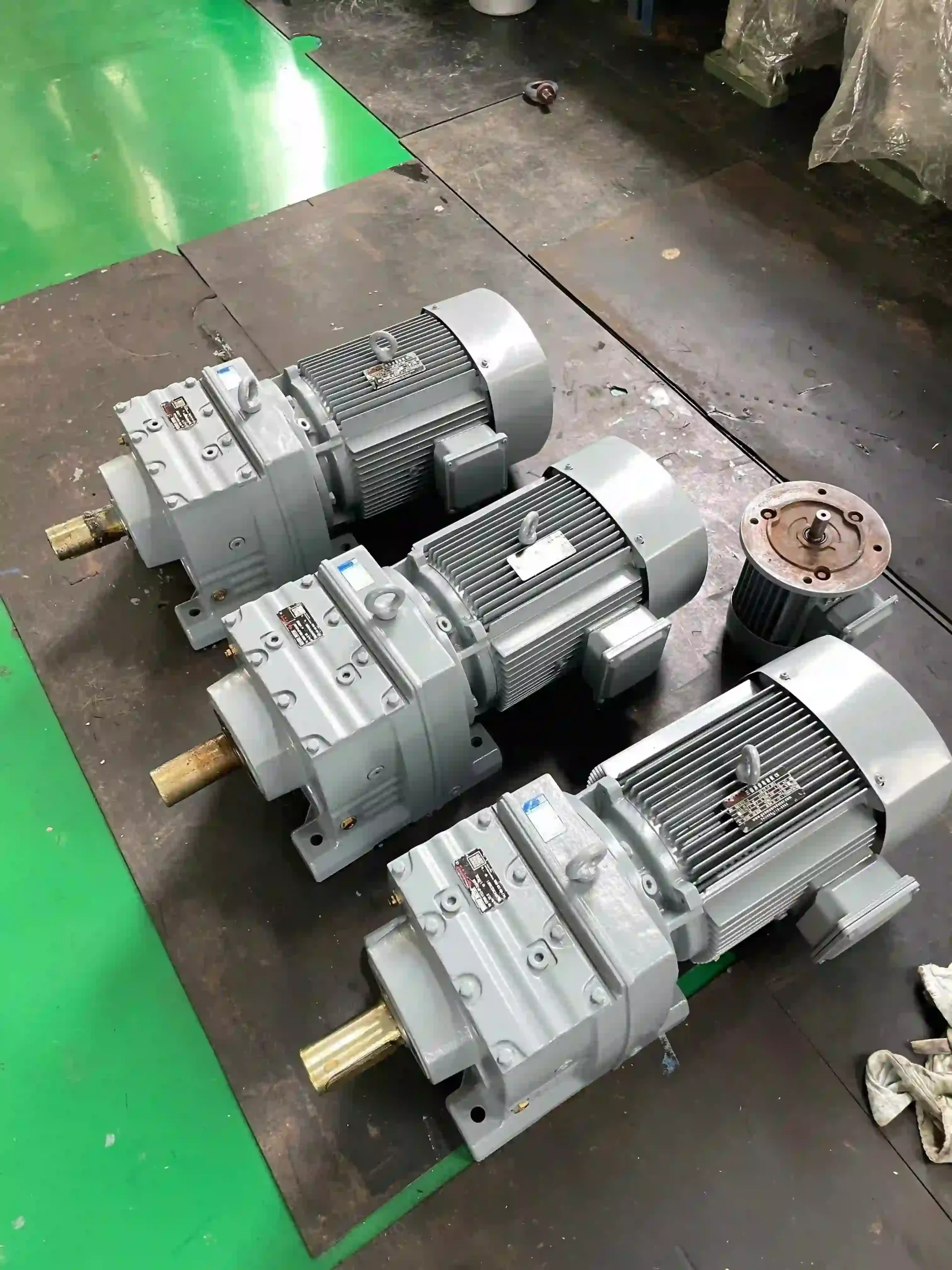

Pequeño no’ t significa débil. En Guomao, nuestros reductores de engranajes helicoidales de eje paralelo de la serie GF y Motor de engranaje helicoidal de la serie GR utilizar carcasas fundidas resistentes y conjuntos de engranajes de precisión. Estas características:

- Mantenga las cosas frescas incluso durante trabajos pesados.

- Permite cajas de cambios más pequeñas y de funcionamiento más frío.

- Soporta carreras largas sin sobrecalentamiento.

Es’ es una victoria para mantener las máquinas zumbido sin sudor.

Funcionamiento suave, silencioso y duradero de cajas de engranajes helicoidales de 2 etapas pesadas

El ruido y las vibraciones son grandes negocios en las industrias pesadas. Con la charla global sobre la salud de los trabajadores y reglas más estrictas, las cajas de cambios silenciosas y suaves son una necesidad, no una bonificación.

Dientes de engranajes helicoidales: bajo ruido y vibración en entornos industriales

Los engranajes helicoidales tienen dientes inclinados que se mallan suavemente, a diferencia de los engranajes espolones que golpean juntos. Esta acción suave:

- Reduce los temblores y las sacudidas.

- Mantiene el ruido bajo en zonas tranquilas.

- Ahorra las partes cercanas, como los motores, del desgaste adicional.

Es’ como un zumbido suave en lugar de un ruido fuerte, haciendo que las zonas de trabajo sean más tranquilas.

Construido para condiciones duraderas: durabilidad en ciclos de carga pesada

Los trabajos pesados empujan las cajas de cambios al límite. Guomao’ Las cajas de cambios helicoidales de 2 etapas se construyen para esto:

- Los engranajes de acero de aleación carbonizados y apagados alcanzan la dureza HRC58-62.

- La molienda de precisión hace que el contacto sea súper suave y dure más tiempo.

- Los rodamientos Beefy manejan cargas pesadas sin parar.

Estos los hacen perfectos para lugares como minas o puertos donde el tiempo de inactividad es un no-go.

Caja de engranajes helicoidal de 2 etapas vs. modelos de una sola etapa: eficiencia y distribución de carga en comparación

Eficiencia energética: multiplicación de par en dos etapas vs. límites en una sola etapa

Con las fábricas empujadas a ahorrar energía y reducir el carbono, la eficiencia es un gran problema. Las cajas de cambios de una sola etapa luchan con altas relaciones de reducción, perdiendo eficiencia rápidamente. Una caja de cambios helicoidal de 2 etapas mantiene la eficiencia por encima del 95%, incluso en condiciones difíciles. Esto ayuda a las empresas a alcanzar metas verdes y ahorrar energía, lo que la convierte en una elección inteligente.

Compartir carga y ventajas de mantenimiento de las cajas de engranajes de dos etapas

Las cajas de cambios de una sola etapa ponen todo el estrés en menos dientes, desgastándolos más rápido. Esto conduce a:

- Desgaste dental más rápido.

- Correcciones más frecuentes.

- Mayores costos de mantenimiento.

Las cajas de cambios helicoidales de dos etapas distribuyen la carga a través de más dientes, por lo que obtiene:

- Menos desgaste.

- Mayor distancia entre el mantenimiento.

- Menores costos con el tiempo.

En eventos como Mundo de la fabricación Osaka 2025La eficiencia y el ahorro a largo plazo son temas calientes. Los compradores quieren cajas de cambios que ahorren energía y duren para siempre. Las cajas de cambios helicoidales de 2 etapas encajan en la factura, convirtiéndolas en una estrella para 2025.

Personalización avanzada y confiabilidad – Guomao’ s Bordo de caja de engranajes helicoidal de 2 etapas

Ingeniería de precisión y fiabilidad pesada única para Guomao

En Guomao, nosotros’ Estamos orgullosos de ser uno de China’ Los principales fabricantes de cajas de cambios, con más de 30 años de experiencia. Con 530.000 m² de espacio de fábrica y una producción anual que supera los 400 millones de USD, nosotros’ somos un gran jugador en el mundo del engranaje. Nuestros reductores de engranajes helicoidales de eje paralelo de la serie GF y los reductores de engranajes helicoidales de la serie GR vienen en configuraciones de 2 etapas, construidos para industrias pesadas. Ofrecen:

- Diseños modulares para configuraciones flexibles.

- Amplias relaciones para diferentes cargas.

- Tamaño compacto con gran potencia de par.

- Resistencia comprobada en ciclos sin parada.

Configuraciones a medida: par, relación, opciones de montaje para uso pesado

Cada industria tiene sus propios desafíos. Guomao artesanía cajas de cambios personalizadas de 2 etapas para:

- Necesidades específicas de par.

- Las opciones de montaje incluyen pie, brida o eje.

- Proporciones que coinciden con trabajos únicos.

Con un historial en minería, metalurgia, puertos y automatización, nuestras cajas de cambios son’ t solo productos—they’ soluciones para el futuro del trabajo pesado.

Preguntas frecuentes

P: ¿Qué es una caja de cambios helicoidal de 2 etapas y cómo funciona?

R: Es’ s una caja de cambios con dos conjuntos de engranajes helicoidales en fila. Cada conjunto reduce la velocidad y aumenta el par, lo que proporciona una mayor potencia y eficiencia que las cajas de cambios de una etapa.

P: ¿Por qué se prefiere una caja de cambios helicoidal de 2 etapas para aplicaciones pesadas?

R: Ofrece un gran par, se mantiene eficiente a altas proporciones, extiende la carga para reducir el desgaste y funciona de manera fiable en trabajos duros y sin parada.

P: ¿Qué tan eficiente es una caja de cambios helicoidal de 2 etapas en comparación con un modelo de una sola etapa?

R: Una buena caja de cambios de 2 etapas alcanza más del 95% de eficiencia, mientras que los modelos de una sola etapa pierden eficiencia con altas relaciones de reducción.

P: ¿Qué industrias suelen usar cajas de cambios helicoidales de 2 etapas?

R: La minería, el acero, la metalurgia, la logística portuaria, la maquinaria de construcción y los transportadores automatizados se apoyan en ellos para un rendimiento resistente y fiable.

P: ¿Guomao proporciona cajas de cambios helicoidales personalizadas de 2 etapas?

R: Sí. Ofrecemos diseños a medida para el par, la relación y las necesidades de montaje. Nuestras series GF y GR incluyen configuraciones de 2 etapas para uso industrial pesado.