Introducción a las cajas de engranajes planetarias modulares

Las cajas de cambios planetarias son piezas clave en muchas industrias. Ellos’ Se utiliza en robótica, aeroespacial y más. Su diseño es pequeño pero fuerte. Esto los hace ideales para máquinas que necesitan una alta salida de par en espacios estrechos. La ventaja clave de las cajas de cambios planetarias modulares radica en su diseño modular, que ofrece una amplia flexibilidad para la personalización.

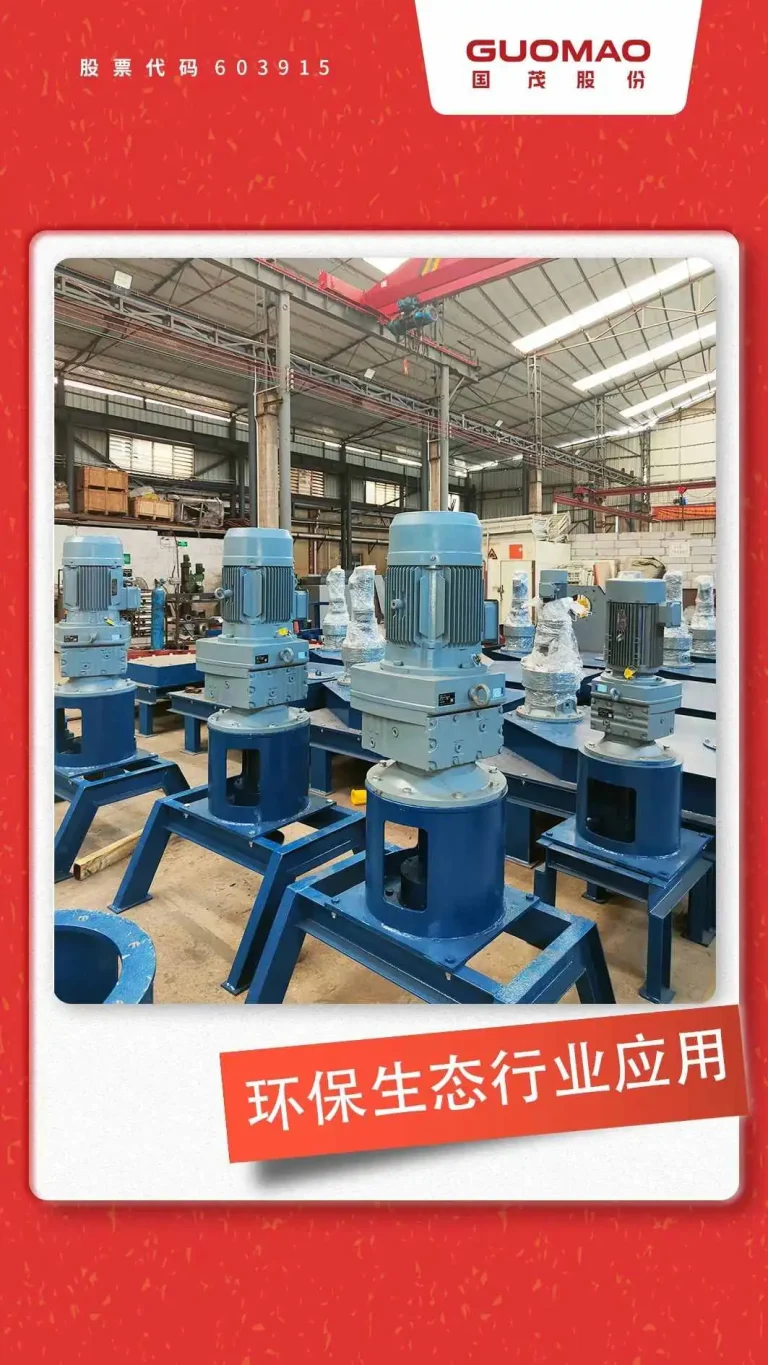

En Guomao, fabricamos cajas de cambios planetarias modulares. Sus diseños se adaptan a diferentes necesidades de potencia y velocidad en campos como la automatización, la construcción y la energía. Ellos’ También es fácil de ajustar para desafíos específicos.

En este artículo ’ Hablaremos de lo que hace que estas cajas de cambios sean especiales. Nosotros’ cubrirán sus beneficios, las industrias a las que ayudan y cómo ahorran dinero mientras se mantienen flexibles.

Características clave de las cajas de engranajes planetarias modulares

Modularidad y personalización

Las cajas de cambios planetarias modulares brillan porque’ somos tan flexibles. Puedes cambiarlos fácilmente. Guomao’ Los diseños ofrecen muchas opciones. Puede elegir piezas como engranajes, ejes, carcasas o configuraciones de entrada/salida. Esto le permite construir una caja de cambios que se ajuste perfectamente a su máquina. Es’ No es un acuerdo de tamaño único para todos.

Puede elegir piezas para mayor potencia, velocidades específicas o una mayor eficiencia. Por ejemplo, seleccionar diferentes relaciones de engranajes o materiales ayuda. Funciona para trabajos pesados o tareas más ligeras. También puede intercambiar o actualizar piezas más tarde. Esto reduce el tiempo de inactividad y los costos de reparación.

Esta flexibilidad hace Guomao’ cajas de cambios s Excelente para muchos campos. Trabajan en la fabricación, automóviles, robótica y energía verde. Ellos’ re fiable y puede crecer con sus necesidades.

Diseño compacto y eficiencia espacial

Las limitaciones de espacio en la maquinaria moderna hacen que las soluciones de engranajes compactos sean esenciales. Las cajas de cambios pequeñas y fuertes están en alta demanda. Guomao’ Las cajas de cambios planetarias modulares están construidas para ahorrar espacio. A pesar de su tamaño compacto, proporcionan una alta densidad de potencia. Su pequeño tamaño encaja en lugares estrechos, como en robots o configuraciones automatizadas donde cada pedazo de espacio importa.

Aplicaciones de cajas de engranajes planetarias modulares en diferentes industrias

Automatización industrial y robótica

Las cajas de cambios personalizables son imprescindibles para la automatización y la robótica. Puedes ajustar su potencia, velocidad o tamaño. Esto los hace perfectos para los robots. Guomao’ Los diseños modulares le permiten ajustarlos para adaptarse a cada trabajo justo. Manejan las necesidades únicas de los sistemas robóticos con facilidad.

Industrias Aeroespaciales y Semiconductores

Los campos aeroespaciales y semiconductores necesitan precisión. También necesitan un equipo que funcione cada vez. Guomao’ Las cajas de cambios planetarias modulares están a la altura de la tarea. En la industria aeroespacial, donde importan el espacio y la precisión, nuestras cajas de cambios alimentan componentes como accionadores y sistemas de control de vuelo. Garantizan un funcionamiento consistente y eficiente.

Nuestra Reductores planetarios de precisión Son excelentes para estos trabajos. Ofrecen una gran potencia y precisión en un paquete pequeño. Puede ajustar las piezas para tareas como sistemas por satélite o máquinas de fabricación de chips. Esto garantiza el máximo rendimiento.

Equipos agrícolas y de construcción

Los equipos agrícolas y de construcción se enfrentan a condiciones difíciles. Las cajas de engranajes deben ser fuertes y fiables. Deben manejar entornos difíciles. Guomao’ Las cajas de cambios planetarias modulares están construidas para esto. Trabajan en máquinas como tractores, cosechadoras o grúas. Gestionan bien diferentes cargas y velocidades.

Los motores engranajes helicoidales de la serie GR son perfectos para la elevación, los transportadores o la manipulación de materiales. Se desempeñan bien en entornos duros. Su diseño modular le permite ajustarlos fácilmente. Esto reduce el tiempo de inactividad y mantiene el mantenimiento bajo.

Beneficios de las cajas de engranajes planetarias modulares sobre las cajas de engranajes tradicionales

Mayor eficiencia

Cajas de cambios planetarias modulares ahorran energía. Guomao’ Los diseños pierden menos energía durante el uso. Esto aumenta el rendimiento general. Puede elegir piezas para obtener la potencia o velocidad exacta que necesita. Esto mantiene el consumo de energía bajo sin perjudicar el rendimiento.

Durabilidad y rendimiento con cargas pesadas

Las cajas de cambios Guomao están diseñadas para trabajar en las condiciones más difíciles y funcionar de manera óptima en las condiciones más estresantes. Hecho de materiales de alta resistencia, las cajas de cambios están diseñadas para soportar cargas pesadas, estrés y temperaturas extremas sin sacrificar la eficiencia o la vida útil. Son pesados y pueden operar continuamente sin problemas, incluso bajo las demandas industriales más estresantes como maquinaria pesada, centrales eléctricas y fábricas.

Lo que diferencia a las cajas de cambios Guomao de otras es que están hechas a medida, y esto le permite diseñar la caja de cambios para satisfacer sus necesidades. Cuando necesita más par, una mejor distribución de carga o eficiencia energética, Guomao’ Las cajas de cambios se pueden desarrollar para satisfacer estos requisitos y ofrecer la máxima eficiencia en diferentes aplicaciones. El hecho de que están hechos de materiales de mayor calidad también significa que son más robustos, reduciendo la tasa de reemplazo y el tiempo de inactividad. Esta es la razón por la que las cajas de cambios Guomao son una inversión a largo plazo que proporciona una salida repetida y de alta potencia día tras día, sin importar las condiciones de funcionamiento difíciles. En la industria, vehículos o operaciones pesadas, las cajas de cambios Guomao están diseñadas para mantener su operación en funcionamiento día tras día.

Eficacia en función de los costos

Las cajas de cambios modulares ahorran dinero. Sus partes pueden ser intercambiadas. Esto evita el alto costo de los sistemas construidos a medida. Guomao’ Los diseños de S le permiten elegir solo lo que necesita. Usted no’ t pagar por extras.

Ellos’ re también duradero y necesita menos fijación. Esto reduce los costos de reparación y el tiempo de inactividad. Para las empresas que quieren ahorrar a largo plazo, las cajas de cambios planetarias modulares son una opción inteligente.

Retos y consideraciones al usar cajas de engranajes planetarias modulares

Instalación e integración

Las cajas de cambios modulares tienen grandes beneficios. Pero instalarlos puede ser complicado. Deben funcionar bien con otras piezas de la máquina. Guomao ofrece guías claras y apoyo. Esto ayuda a que nuestras cajas de cambios encajen sin problemas en muchos sistemas.

Límites de personalización

Las cajas de cambios modulares ofrecen muchos ajustes. Pero hay algunos límites. Usted puede’ T cambia todo. Trabajar con Guomao’ El equipo de ingeniería ayuda. Nos aseguramos de que sus necesidades se satisfagan sin dañar la caja de cambios’ rendimiento o fiabilidad.

Preguntas frecuentes

P: ¿Cuáles son las ventajas clave de las cajas de cambios planetarias modulares?

R: Son flexibles, eficientes en el espacio, ahorran energía y son duraderos. Por lo tanto, son ampliamente aplicables en una amplia gama de industrias.

P: ¿Cómo pueden diseñarse las cajas de cambios planetarias modulares para satisfacer diferentes aplicaciones?

R: Modificar las relaciones de engranajes, la potencia de salida o los tipos de configuración para cumplir con requisitos específicos.

P: ¿Qué industrias utilizan más cajas de cambios planetarias modulares?

R: Aeroespacial, construcción, agricultura, automatización y robótica aprovechan al máximo la fuerza y flexibilidad de estas cajas de cambios.

P: ¿Son las cajas de cambios planetarias modulares adecuadas para el par pesado?

A: Lo son. Ellos’ re hecho para manejar cargas pesadas. Ellos’ re duro y desempeñar bien en entornos difíciles.

P: ¿Qué tipo de mantenimiento necesitan las cajas de cambios planetarias modulares de forma regular?

R: Necesitan muy poco mantenimiento. Se operan, inspeccionan rutinariamente, engrasan y inspeccionan el desgaste durante años de condiciones de funcionamiento máximas.