Introduction to Cylindrical Gear Reducers and Their Role in Modern Industry

What Are Cylindrical Gear Reducers?

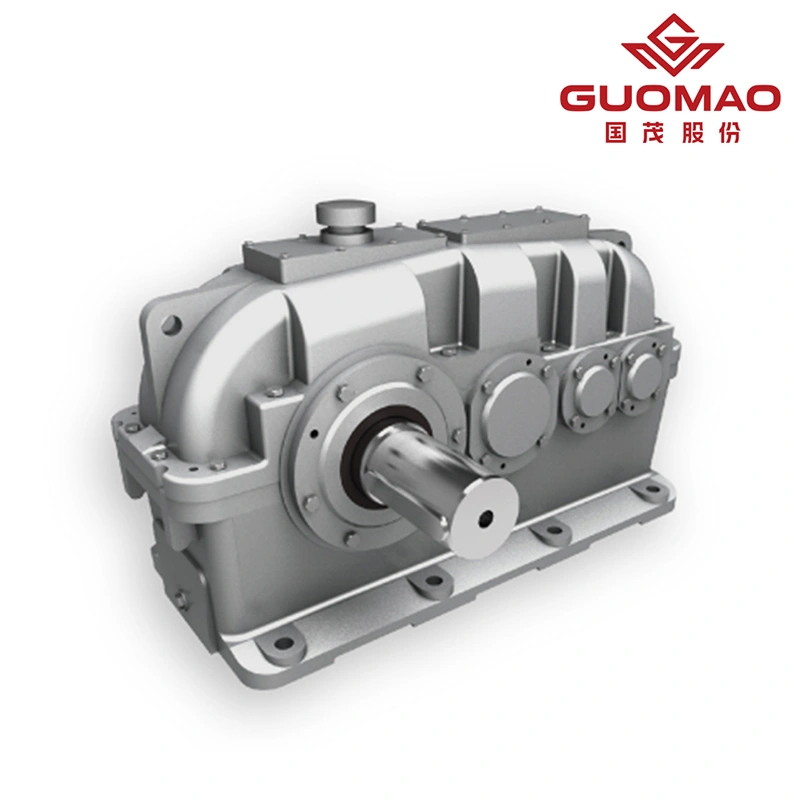

Cylindrical gear reducers are mechanical tools built to slow down motor speeds. At the same time, they boost torque. These devices pass power along parallel shafts via cylindrical gears. That setup fits them for many industrial uses. They can tweak both speed and torque. As a result, cylindrical gear reducers improve machine output. They deliver better power transfer. This works well in tough, high-torque settings.

The Importance of Cylindrical Gear Reducers in Industrial Applications

In today’s industry, cylindrical gear reducers play a vital role. They help machinery run smoothly and dependably. This holds true in areas like manufacturing, mining, or energy. These tools keep systems efficient. They offer precise control, low upkeep, and strong build. Guomao’s ZY Series Cylindrical Gear Reducer, for instance, handles power transfer well. It suits spots like automotive and food processing. There, steady work and trust matter most.

Key Trends Shaping the Cylindrical Gear Reducer Market in 2026

Emerging Industrial Applications Driving Demand for Cylindrical Gear Reducers

The market for cylindrical gear reducers grows quickly. Industries seek better machines that save energy and perform well. Fields like robotics, automation, and renewable energy use them more. These sectors want precision and lower power use. Automation now forms a big part of manufacturing. Thus, the need for cylindrical gear reducers rises. They must work efficiently on ongoing tasks.

Technological Advancements: How the Cylindrical Gear Reducer is Evolving

Cylindrical gear reducers have changed a lot. This comes from better materials, production methods, and designs. Now, they last longer, take up less space, and manage bigger loads at quicker paces. A key improvement is sharper gear cutting. It cuts down friction and extends use time. Plus, better lubrication and seals boost life and output. They handle tough demands in mining and manufacturing.

Guomao’s ZDY type reducer uses these updates. It provides top strength and strong torque. That makes it great for hard tasks like wind turbine gearboxes and energy setups.

Major Industries Benefiting from Cylindrical Gear Reducers

Manufacturing and Automation: Efficiency Gains with Cylindrical Gear Reducers

Manufacturing and automation support many processes. Cylindrical gear reducers sit at the center of it all. They make sure machines hit the right speeds. They also keep power steady. This cuts energy use and lifts output. Sectors such as automotive, food processing, and packaging depend on them. These devices ensure nonstop, reliable power transfer in automated setups.

Guomao’s ZY Series Cylindrical Gear Reducer sees wide use here. It manages heavy loads with good efficiency. Businesses gain more output and lower costs as a result.

Mining and Heavy-Duty Applications: Reliability and Durability in Demanding Environments

Mining and heavy machinery deal with rough spots. Think high torque and steady shakes. Cylindrical gear reducers prove key in these areas. They keep equipment running even in tough spots. These reducers handle more weight and last longer. So, they cut repair needs and boost gear trust overall.

Guomao’s ZLY type reducer fits these hard conditions. Its tough build and strong load support work well. It suits mining conveyors, crushers, and other big machines.

Energy and Renewable Sectors: Optimizing Performance with Cylindrical Gear Reducers

Renewable energy, like wind and solar, needs gear reducers that turn motion into power well. Cylindrical gear reducers help here. They limit energy waste and max out output. Systems such as wind turbines rely on solid power transfer. This keeps steady work, even in far-off places.

Guomao’s ZDY type reducer fits the energy field. Its strong torque and lasting build ensure good results in hard spots. This line shines in wind energy, where trust and long life count.

How Guomao’s Cylindrical Gear Reducers Solve Industry Challenges and Lead the Market

Precision and Power: The Benefits of Guomao’s Cylindrical Gear Reducers in Reducing Downtime

A main issue for industries is cutting stop times and keeping work going. Guomao’s cylindrical gear reducers tackle this. They provide exact and effective power transfer. That lessens part wear, cuts repair calls, and drops running expenses. Machinery runs well under big loads. Thus, Guomao’s items help hit peak output.

The ZY Series Cylindrical Gear Reducer stands out here. It handles high torque with trust. This cuts stop times in key tasks a lot.

Custom Solutions: Tailored Cylindrical Gear Reducers for Industry-Specific Needs

At Guomao, we get that each field has its own hurdles. So, we supply custom cylindrical gear reducers. They match exact needs. This could mean fitting load sizes, speed rates, or site conditions. Our items give the bend needed for different industrial uses.

Take the ZLY type reducer as an example. It adjusts to fit material handling, packaging, and transport needs. That brings top output and trust.

Guomao’s Engineering Expertise: Delivering High-Performance Solutions for Industries Worldwide

Guomao leads in the Cylindrical gear reducer field. We offer strong solutions for global industries. Years of skill in engineering back us. Our products stress great strength, trust, and output. We stay committed to new ideas. This way, we meet shifting needs in current industries.

A Commitment to Innovation: How Guomao’s R&D Focuses on Industrial Challenges

Innovation drives Guomao. We put money into research and development all the time. This improves our cylindrical gear reducers. It also fixes changing issues in industries. By aiming for steady gains, our products stay ahead in tech. We give the top fixes for power transfer demands.

FAQ

Q: What is the function of a cylindrical gear reducer in industrial applications?

A: A cylindrical gear reducer reduces the speed of a motor and increases the torque. This device is significant in various applications, such as manufacturing, mining, and renewable power. Guomao’s ZY Series Cylindrical Gear Reducer and ZLY type reducer guarantee reliable power transmission in harsh environments.

Q: How do I choose the right cylindrical gear reducer for my needs?

A: To pick a cylindrical gear reducer, look at load size, output, and work site. Choose one with options to fit exact uses. Guomao provides custom items like the ZDY type reducer for different industrial wants.

Q: Cylindrical Gear Reducer vs Helical Gear Reducer: What are the differences?

A: Cylindrical gear reducers work for parallel shaft tasks. They manage high torque well. That fits heavy machines. Guomao’s ZY Series Cylindrical Gear Reducer gives strong results there. Helical gear reducers suit quieter, smoother runs in easier spots.

Q: Which brands offer the best cylindrical gear reducers for heavy-duty industries?

A: Guomao tops the list for cylindrical gear reducers. We supply quality, lasting fixes for worldwide industries. Our ZLY type reducer and ZY Series Cylindrical Gear Reducer fit heavy tasks in mining and manufacturing.

Q: How do cylindrical gear reducers benefit industries such as energy and mining?

A: Cylindrical gear reducers matter in energy and mining. They ensure solid power transfer and good runs in rough spots. Guomao’s ZDY type reducer suits renewable energy well. It offers high output and strength for wind systems.