Industries today need machines that are accurate, strong, and save energy. Finding a gearbox that hits all these marks is tricky. Two-stage helical gearboxes are a solid pick for complex systems. They deliver powerful torque and slower speeds in a small, easy-to-use package. Guomao crafts trusty two-stage helical gearboxes for all sorts of industries. This article explains why these gearboxes work so well in tough setups. It also shows how Guomao’s products make your work better.

What Are Two-Stage Helical Gearboxes?

Definition and Operating Principle

A two-stage helical gearbox uses two sets of helical gears, one after the other. The first set slows the input speed a lot. The second set brings it down even more. These gears have angled teeth. That makes them run smoothly and quietly compared to straight-tooth gears. They pack strong torque into a tight space. This is perfect when you need power but don’t have much room. Really handy, right?

Key Components

Helical Gears: Angled teeth keep things quiet and steady with little shaking.

Bearings: These support moving parts. They reduce friction and make motion smooth.

Housing: A tough shell protects the insides. It also boosts strength.

Lubrication System: Good oiling keeps heat down. It helps the gearbox last longer.

How Do Two-Stage Helical Gearboxes Optimize Space and Weight?

Compact Design

Two-stage helical gearboxes are built to save space. Their gear setup gives big torque in a small package. This is great for systems with tight spots, like robotics, car parts, or heavy machines. Guomao’s two-stage helical gearboxes slide right in. They operate efficiently without requiring additional installation space, making them a practical solution for compact system designs.

High Torque Density

The two-stage system handles big torque while staying small. It spreads force across multiple gears. Each gear is compact but super strong. This keeps the gearbox light and small compared to others. The mix of power and size is perfect for jobs needing strong output in tight spaces. It keeps things running like a charm.

Efficient Use of Materials

Guomao uses strong, lightweight alloys in its Helical Gearbox Series. These materials make the gearbox tough without piling on weight. This matters a lot in fields like aerospace or cars, where keeping things light is key. You still get strength and performance. Guomao’s gearboxes balance both needs well.

Space-Efficient Heat Dissipation

The design spreads heat evenly across the gearbox. This stops it from getting too hot. It keeps performance steady without needing big cooling systems. That saves space. The gearbox stays trusty in tough conditions. It’s ideal for small, high-power systems where heat control matters.

How Do Two-Stage Helical Gearboxes Enhance Efficiency and Performance?

Smooth and Quiet Operation

The angled teeth of helical gears mesh nice and easy. This cuts down noise and shaking compared to regular gears. It’s great for jobs needing quiet performance, like robotics, medical tools, or precise machines. The smoother action means less wear. The gearbox stays trusty and lasts longer.

High Load-Carrying Capacity

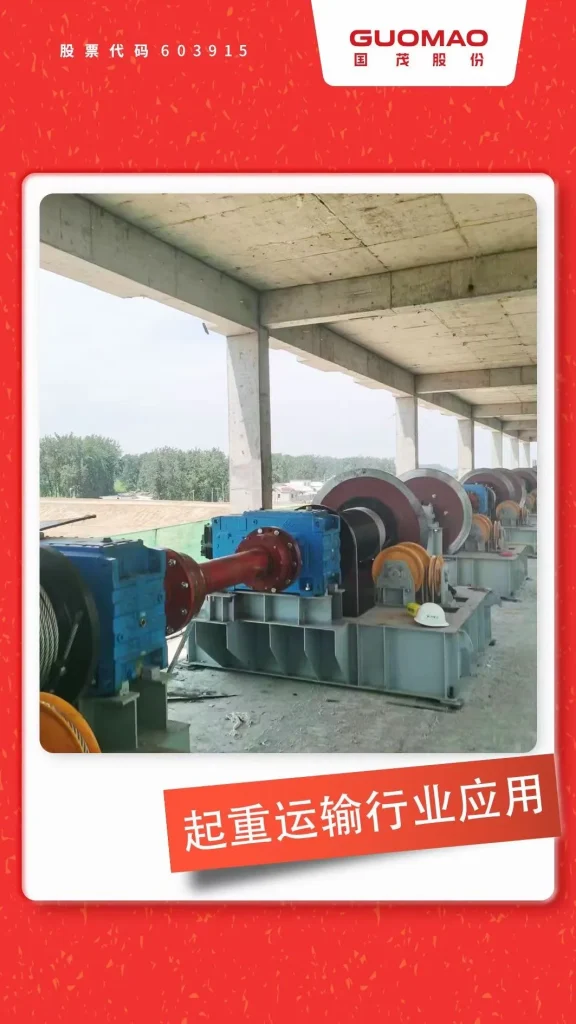

Two-stage helical gearboxes spread loads across many teeth. They handle heavier loads than single-stage models. This makes them perfect for tough tasks in cranes, conveyors, or factory machines. Their strong build keeps them steady, even under big pressure.

Reduced Wear and Tear

The smooth running of helical gears lowers wear on parts. This is super important for heavy jobs. The design cuts stress on components. It also reduces impact forces. You need fewer fixes. The gearbox stays strong for years. This saves cash and keeps your operations smooth.

How Do Two-Stage Helical Gearboxes Contribute to System Stability?

Balanced Axial Thrust

Helical gears create some axial thrust because of their angled teeth. The two-stage design handles this force well. It cuts down the need for extra thrust bearings. This keeps the system lined up and stable. It ensures steady performance for all kinds of tasks.

Thermal Management

Keeping heat in check is crucial for safe operation. Guomao’s two-stage helical gearboxes manage heat really well. They avoid getting too hot, even during tough use. A good cooling system keeps performance steady in hard conditions. This makes them dependable for long-term work.

How to Select the Right Two-Stage Helical Gearbox

Assessing Load and Speed Requirements

Start by looking at your system’s load and speed needs. Guomao offers a range of helical gearboxes with different torque and speed options. The Helical Gearbox Series fits heavy machinery or precise robotic setups. Picking the right model boosts efficiency and saves energy.

Material Selection and Durability

The materials in a gearbox affect how strong and long-lasting it is. For tough jobs, choose gearboxes made from durable materials. Guomao uses high-quality alloys. Our two-stage helical gearboxes hold up in harsh conditions. They keep your operations running smoothly.

Environmental Compatibility

The work environment can affect gearbox performance. Heat, moisture, or dust can cause problems. Guomao’s two-stage helical gearboxes are built to handle all sorts of conditions. They deliver steady performance, no matter the challenge.

Why Choose Guomao’s Two-Stage Helical Gearboxes?

Precision Engineering

Guomao builds each gearbox with great care. Our two-stage helical gearboxes offer strong performance, efficiency, and reliability across many uses. This delivers consistent results. It helps customers keep their operations running smoothly.

Durability and Longevity

Guomao’s gearboxes are made to last. We use top-notch materials and modern building techniques. These gearboxes stand up to tough conditions, whether in factory machines, robotics, or car systems. They cut down on fixes and downtime. You get a performance that lasts.

Wide Range of Applications

Guomao’s two-stage helical gearboxes are super versatile. They work in industries like manufacturing, robotics, aerospace, and renewable energy. Their small size, high efficiency, and reliability make them ideal for systems needing power and space savings. They shine in tasks like wind turbines or solar trackers, giving steady results.

FAQ

Q: What is the most great feature of a two-stage helical gearbox?

A: It provides a compact design with powerful torque. It runs smoothly and keeps noise low. This mix is perfect for tasks needing steady power and accurate movement. Really handy, isn’t it?

Q: In what ways are two-stage helical gearboxes better than single-stage gearboxes?

A: They offer stronger torque and more precise speed control. The two-stage setup makes them flexible. They also save space, which is a big plus.

Q: Will two-stage helical gearboxes handle heavy loads?

A: Yes, they are built for tough load demands. Multiple gears share the load. This lets them deliver more torque than single-stage models.

Q: Can Guomao’s two-stage helical gearboxes be customized?

A: Yes. Guomao provides flexible design options for different applications. Torque settings or mounting styles can be adjusted to fit specific project needs.

Q: Which industries gain the most from two-stage helical gearboxes?

A: Areas like robotics, aerospace, car manufacturing, and factory automation gain greatly from their strength and compact size. They are also a great match for green energy systems, like wind power or solar positioning equipment.