What Makes Planetary Speed Reducers Ideal for Compact Designs?

The Unique Structural Advantages of Planetary Speed Reducers

Planetary gearboxes are well known for their structural layout that incorporates the planetary transmission concept to align the input and output shafts along the same axis effectively, reducing the overall size of the system due to its compact design feature. A good example is the Cycloidal Reducer that utilizes this concept with a mechanism, involving cycloidal needles and gear meshing for a more compact and smaller build. Furthermore, gearboxes in systems have multiple gears engaging at once, which boosts torque transmission efficiency all while keeping a small physical footprint.

How Planetary Speed Reducers Minimize Space Requirements

The small size of planetary speed reducers helps save space in machine setups by allowing for high reduction ratios in a stage transmission setup, which is crucial for optimizing space usage effectively and efficiently while ensuring high levels of efficiency exceeding 90%. Stage planetary reducers can achieve reduction ratios up to 1:87, and when configured in multi-stage setups can enhance these ratios even further without the need for bulky additional components, making them perfect for applications where space constraints are a concern.

Furthermore, the parallel positioning of the input and output shafts makes the setup and incorporation into systems easier. The smaller size does not impact performance negatively. It permits engineers to create more compact and effective equipment arrangements without compromising on functionality.

The Role of Weight Optimization in Planetary Speed Reducers

Planetary speed reducers have the advantage of weight optimization, delivering high torque without unnecessary bulk due to their lightweight and sturdy design elements. These precision models incorporate case-hardened helical satellite and sun gears for superior transmission efficiency at low weight levels. This enhanced weight efficiency is especially advantageous in situations that demand mobility or prioritize minimizing the weight of the system.

How Do Planetary Speed Reducers Enhance Efficiency Without Compromising Size?

The Mechanism Behind Efficiency in Planetary Speed Reducers

Planetary gearboxes are specially crafted to provide top-notch efficiency thanks to their design and operational methods. Using the planetary transmission system allows these gearboxes to generate torque and maintain precise control over motion.

Planetary gearboxes are specially crafted to provide top-notch efficiency thanks to their design and operational methods. Using the planetary transmission system allows these gearboxes to generate torque and maintain precise control over motion.

Their secret to success lies in the equal loading of load across different planet gears. Since the load is shared, each gear experiences lower stress, and hence less wear and longer unit life. The other benefit of planetary reducers is that they are capable of having a high ratio of reduction, enabling smooth and efficient speed reduction without compromising on power output.

With the application of advanced materials and high-precision manufacturing, planetary speed reducers can achieve high efficiency levels while still being designed to occupy little space. They thus make for a perfect fit in industries such as robotics, industrial and automotive machinery, where performance and space are usually in short supply.

Balancing Performance and Size with Guomao’s Solutions

Guomao’s Precision Planetary Reducer is a blend of space-saving and efficiency. It consists of a minimized design that offers a maximum torque output of as much as 850,000 kNm yet remains in a very limited space. This positions it as a top choice for applications, which demand a lot of power in a very limited space.

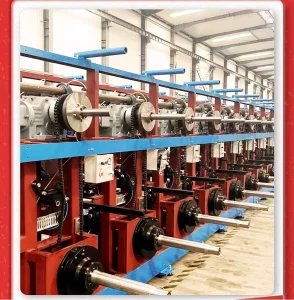

Guomao’s planetary gear reducers are renowned for their ability to meet working demands effectively because of their high-precision engineering techniques that ensure uniform performance in a broad spectrum of industries. For instance, each satellite gear in the reducers is supported by the full complement needle bearings, which offer torsional stiffness and smooth running even under heavy loads.

What Factors Should Be Considered When Selecting a Planetary Speed Reducer?

Load Capacity and Torque Requirements

When selecting a planetary speed reducer for your application, it is vital to pay special attention to the load capacity and torque requirements of your application. Additionally, consideration of the working environment of the planetary speed reducer is essential. Systems that experience starting and stopping or varying loads require components with high overload capabilities and resistance to impact.

Gear Ratio Selection for Optimal Performance

Choosing the right gear ratio is extremely crucial in achieving the performance and efficiency of your machinery or equipment. Planetary speed reducers are most famous for their capability to achieve reduction ratios in a compact size. A stage planetary reducer can achieve reduction ratios of up to 1:87 with efficiencies over 90%, and in multi-stage designs, these ratios can be even higher.

Guomao’s Precision Planetary Reducer provides speed ratios from 30 to 160 that can be adjusted to suit industrial requirements, including robotics and aerospace uses with ease. The tailored gear ratio selection allows engineers to fine-tune the performance according to particular working requirements.

Why Choose Guomao’s Planetary Speed Reducers for Your Design Needs?

Key Features of Guomao’s Planetary Speed Reducers

Precision Engineering for Reliable Performance

Guomao utilizes engineering methods to guarantee consistent functionality in its line of planetary gear reducers. All satellite gears are backed by supports with complete needle bearings to boost torsional rigidity and ensure seamless functioning. Additionally, the gear design aids in reducing noise levels and enhancing transmission precision overall.

Durability and Long Service Life

Guomao’s products are known for their durability as they are made with materials, like case hardened steel to ensure key parts can handle tough loads and last long without wearing out quickly.

Applications of Guomao’s Planetary Speed Reducers in Space-Saving Designs

Guomao’s planetary speed reducers are widely used in industries that require compact designs, such as:

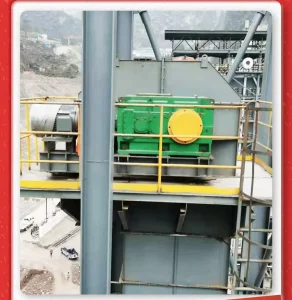

- Engineering Machinery: In road rollers, pavers, milling machines and tower cranes, Guomao’s planetary reducers provide high torque output within compact dimensions.

- Marine Machinery: Their IP65-rated protection against dust infiltration and water jets makes them suitable for marine environments.

- Industrial Robotics: Precision planetary reducers cater to the needs of industrial robots by offering customizable speed ratios (30-160) alongside enhanced rigidity.

- Construction Equipment: From rotary drilling rigs to hoisting machinery, their lightweight yet powerful design supports efficient operation in confined spaces.

Guomao’s planetary speed reducers showcase real-world uses that effectively tackle both performance and space limitations. If you have any questions, please contact us!

Frequently Asked Questions about Planetary Speed Reducer

Q: What is a planetary speed reducer?

A: Planetary gear reducers are special gearboxes that give a high ratio reduction in a compact package. Whereas regular gearboxes have a single gear that is involved, planetary gearboxes have multiple gears (or “planets”) which orbit around a central gear.

Q: Which is an advantage of a planetary gear reducer?

A: Planetary gear reducers benefit small and large systems by being able to effectively reduce speed and the torsional inertia ratio of the system and also multiply torque within the system.

Q: What does a speed reducer do?

A: Planetary gear reducers, or planetary speed reducers, are mechanical power transmission components that reduce the speed of power transmission from a motor to machinery. Their main purpose is to multiply the torque of the power source to enable higher work capacities.

Q: How do planetary speed reducers improve mechanical efficiency?

A: Planetary speed reducers increase mechanical efficiency by sharing the load through a number of gears equally. This reduces wear, energy loss, and increases torque transmission, which results in quieter operation and increased machinery longevity.